I hope I'm not late for work!

#1761

TECH Veteran

iTrader: (5)

I had Gates hose fail twice. I heated the flexible plastic hose by holding the end in hot oil on the stove to get it hot enough to soften., because boiling water wasn't hot enough. There's a narrow temperature range between softening and melting, so have a spare hose if anybody is going to try it. Sorry I don't remember, I think it was 300 degrees. I was determined to make it fit after having two failures with the Gates hose.

#1764

Yea considering the gates hose right next to the failed one is perfectly fine I am just going to replace the failed one with the gates that should be here today. I am thinking the installed height was off so when it was installed the second hose was stretched instead of relaxed so I am going to be more careful about installed height to make sure its relaxed when installed.

#1767

Admin

iTrader: (22)

I had Gates hose fail twice. I heated the flexible plastic hose by holding the end in hot oil on the stove to get it hot enough to soften., because boiling water wasn't hot enough. There's a narrow temperature range between softening and melting, so have a spare hose if anybody is going to try it. Sorry I don't remember, I think it was 300 degrees. I was determined to make it fit after having two failures with the Gates hose.

Thanks for joining in....... Lol

#1769

You people

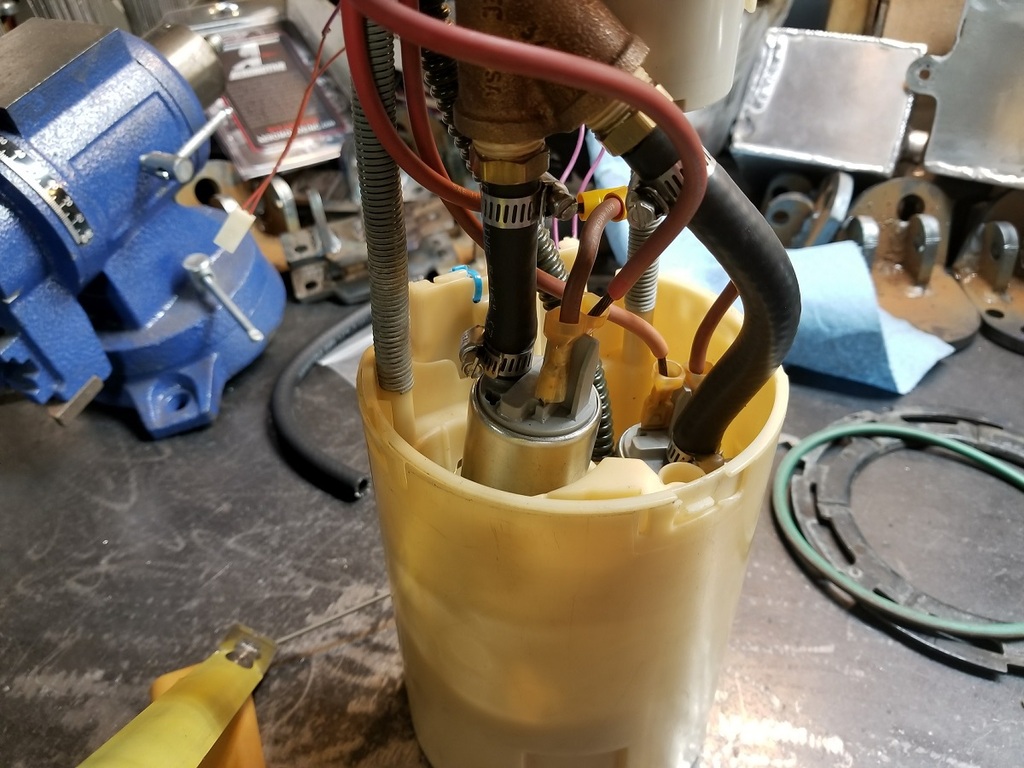

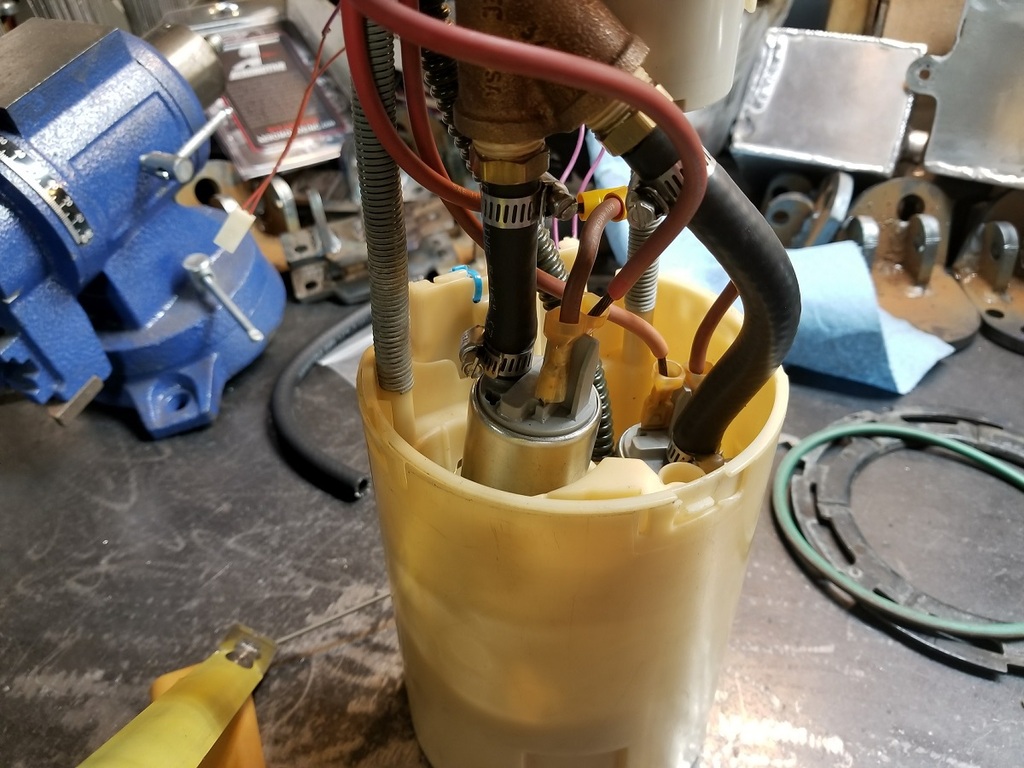

Got it fixed last night and made sure to compress it to the installed height first, ended up only needing a 2.5" section of hose to fix it. Straight shot from the pump to the barb. Its also funny just how big this bucket is. Tons of room in there for fluid to keep the pumps submerged. No external holes except for the flapper valves at the bottom. My setup is a bit bastardized, its an 05 bottom bucket with an 07 top in an 07 tank.

Installed and tested both pumps and everything is good now. Also got the reference line to the cutout ran to a vacuum block off the lower manifold.

Got it fixed last night and made sure to compress it to the installed height first, ended up only needing a 2.5" section of hose to fix it. Straight shot from the pump to the barb. Its also funny just how big this bucket is. Tons of room in there for fluid to keep the pumps submerged. No external holes except for the flapper valves at the bottom. My setup is a bit bastardized, its an 05 bottom bucket with an 07 top in an 07 tank.

Installed and tested both pumps and everything is good now. Also got the reference line to the cutout ran to a vacuum block off the lower manifold.