ILuvJDM's 2007 NBS RCSB Build - Turbo/4L80e/Coilovers/Wilwoods

#41

Decided to permanently mount my intercooler today, started with remounting the ambient temperature sensor. Just drilled a hole in the headlight bracket

Radiator support level

Intercooler to match, don't hate on my custom brackets I made with a hammer and vice

Routed the coolant hoses under the intake

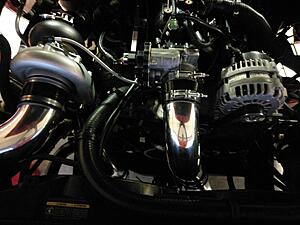

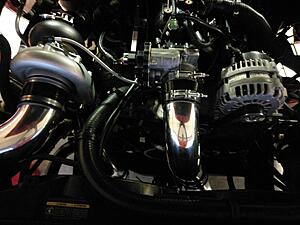

Got all the intercooler piping installed

Got too dark to take good pictures, but got the BOV vacuum line ran along with the MAF wiring. Routed it along the upper coolant hose down the fan wiring. Looks nice and clean and away from hot or moving parts

Radiator support level

Intercooler to match, don't hate on my custom brackets I made with a hammer and vice

Routed the coolant hoses under the intake

Got all the intercooler piping installed

Got too dark to take good pictures, but got the BOV vacuum line ran along with the MAF wiring. Routed it along the upper coolant hose down the fan wiring. Looks nice and clean and away from hot or moving parts

#43

Here's some pictures I never got around to posting:

MAF wiring and vacuum hose for BOV routed down the fans for a clean look away from the engine pulleys

Back when I did the trucool 40k, I bypassed the radiator and didn't just want to leave it open to the elements, so I cut off the ends of the hardlines before I tossed them. Installed them back in the cooler with a vacuum cap for a nice clean look that also keeps crap out of the cooler in case it ever gets hooked back up

Coilovers supplied by Atomic permanently installed and set at pretty close to final ride height, although it's tough to measure because the back end is so high right now making it seem lower than it is

Out in the sunlight

I do have a leak at the oil drain line due to the barb fitting supplied with the kit. I'm not a fan of having plumbing supply house fittings on a vehicle, so I think I'll just bite the bullet and do -10AN

MAF wiring and vacuum hose for BOV routed down the fans for a clean look away from the engine pulleys

Back when I did the trucool 40k, I bypassed the radiator and didn't just want to leave it open to the elements, so I cut off the ends of the hardlines before I tossed them. Installed them back in the cooler with a vacuum cap for a nice clean look that also keeps crap out of the cooler in case it ever gets hooked back up

Coilovers supplied by Atomic permanently installed and set at pretty close to final ride height, although it's tough to measure because the back end is so high right now making it seem lower than it is

Out in the sunlight

I do have a leak at the oil drain line due to the barb fitting supplied with the kit. I'm not a fan of having plumbing supply house fittings on a vehicle, so I think I'll just bite the bullet and do -10AN

#45

You can see that it's so tight in there, that you can't even slide the DEI fire sleeve up all the way. Also, the compressor housing can't be clocked according to the pictures in the installation manual, because the bolts for the compressor cover hit the oil drain line as you rotate it around.

The bottom brass barb that goes into the oil pan is the one that's leaking though, since it's the horizontal fitting.

The upper brackets actually aren't yours, I ordered them with the lower control arms, so they didn't come with any hardware at all. I went to tractor supply to get grade 8 hardware, but was surprised to see no locking nuts like you supplied with your brackets. I know they sell them because I've bought from them before, but maybe they changed suppliers...

#47

I didn't feel like getting dirty tonight, so I worked on my gauge mounting. I'm putting the AEM wideband on top of the steering column, similar to how it was in my old Evo.

I bought a $12 eBay "Defi style" gauge pod and cut up the bottom mount and made it come through the bottom of the plastic so it's nice and hidden.

It's hard to get the picture to show it well, but from the drivers seat, nothing is blocked from view, except 120mph number and the low fuel yellow light

Also tried plastic weld to mount the dual gauge pod on a spare a-pillar I had laying around.

#49

I considered doing that, and I may have to when I switch to AN fittings, but for now I got it to work with the couplers and stuff. You understand how odd it is though that you have to leave a bolt out of something just to get it to work in a normal application... Little things that annoy me