{Project} White Noise- 2005 ECSB 2wd Silverado, Forged 402/4l80e/PTE 88mm turbo

#21

Launching!

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: Minnesota

Posts: 299

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the compliments. Hoping to pick up more speed on the build soon. I've only got a few months left to my dead line of Powecruise!

#23

Launching!

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: Minnesota

Posts: 299

Likes: 0

Received 0 Likes

on

0 Posts

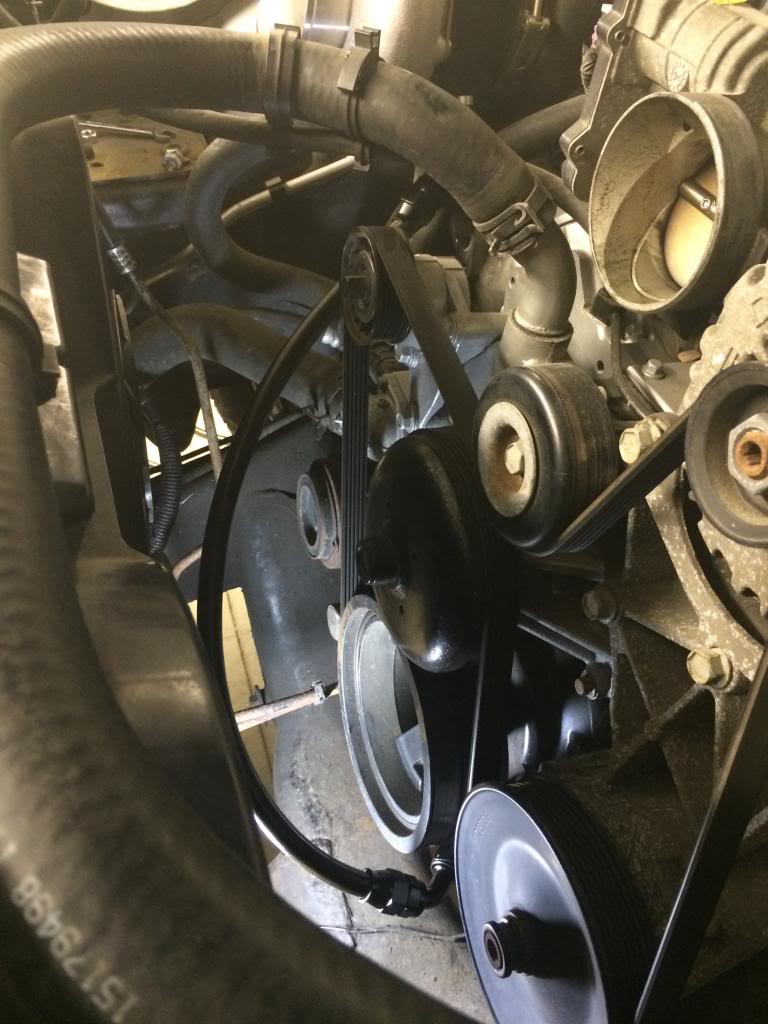

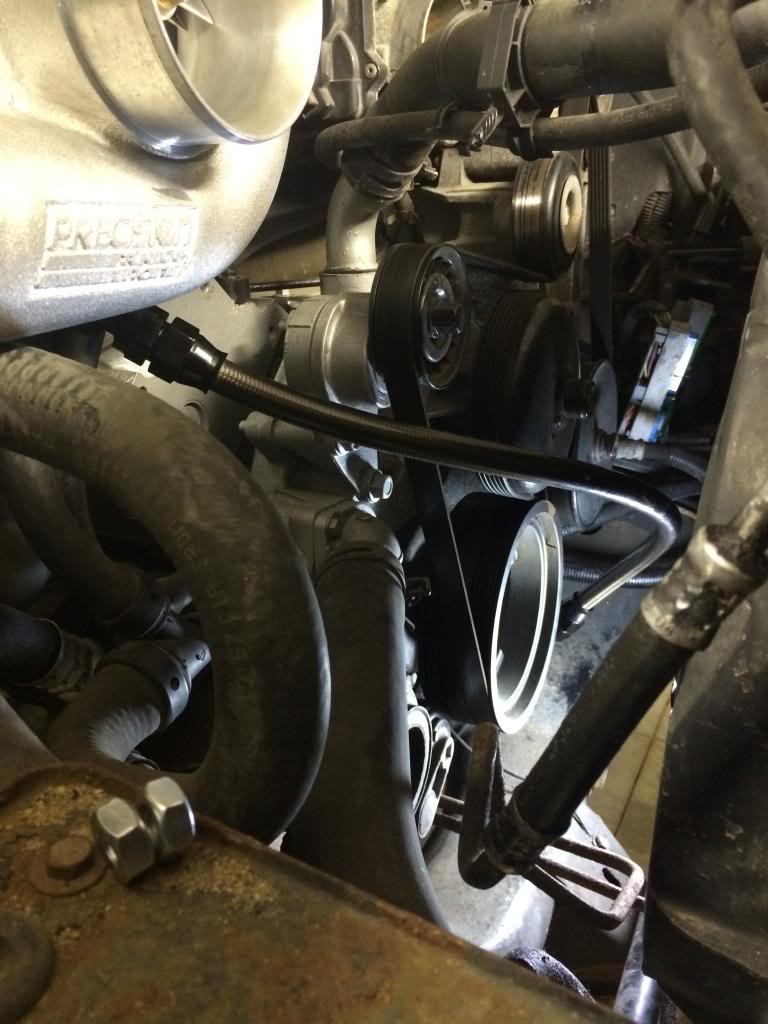

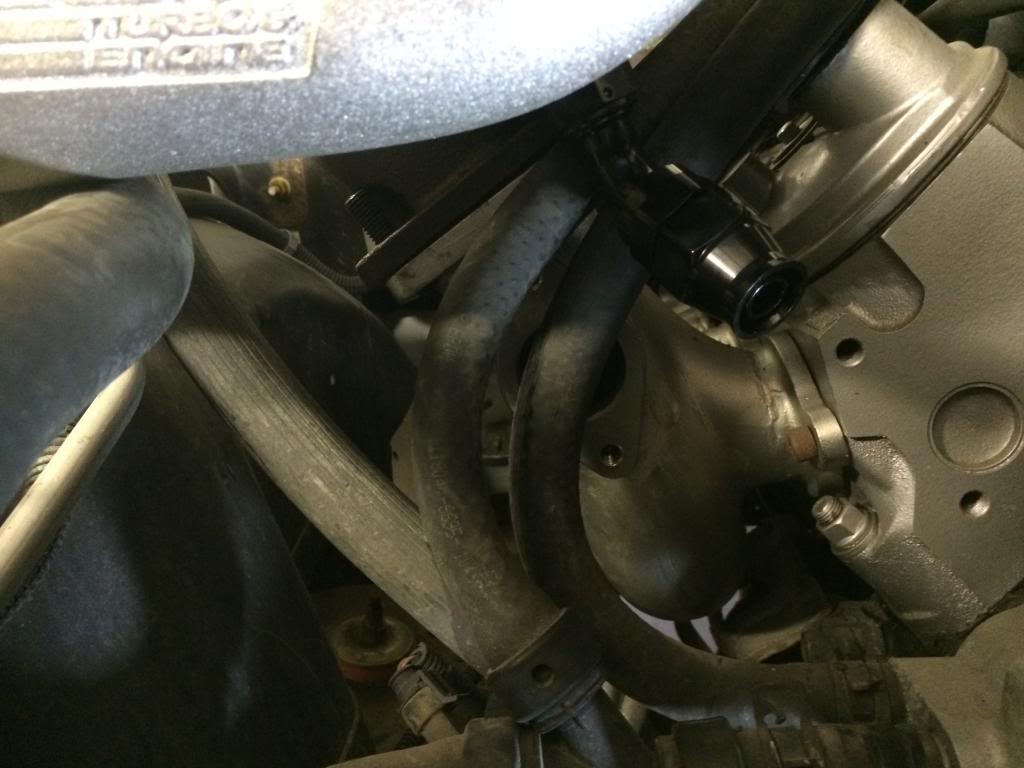

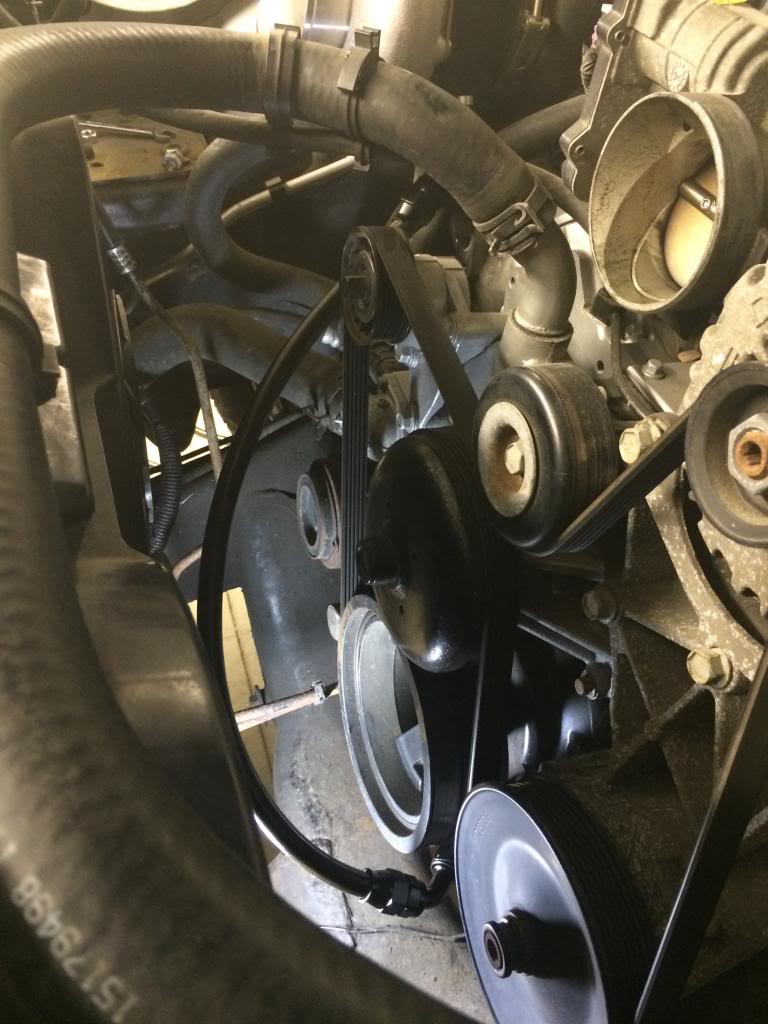

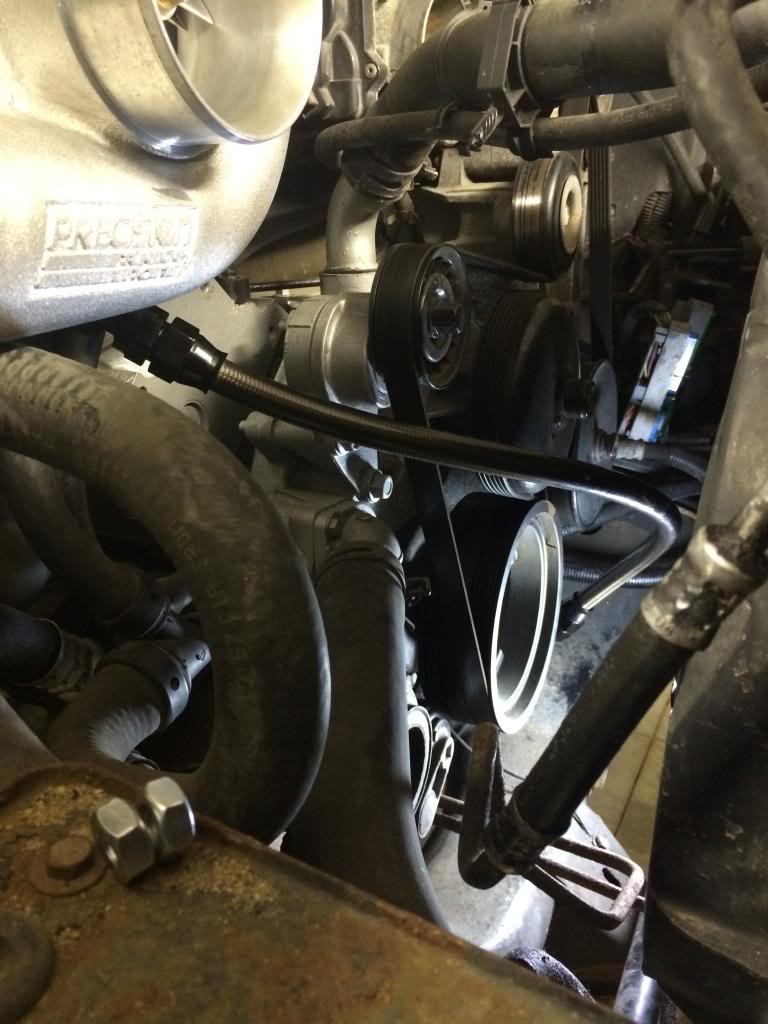

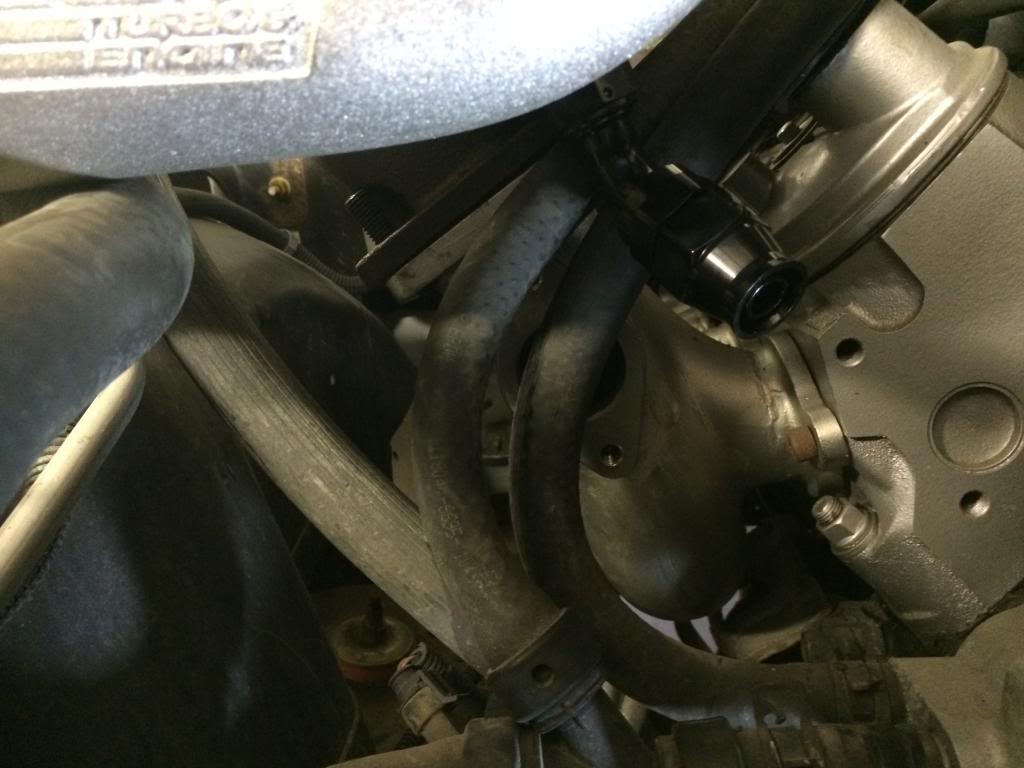

I ran into a stupid problem the other night. The fitting I tapped into my oil pan for the turbo return was just slightly in the wrong place. I installed the -10 straight end last year when I built the motor and place it according to other ones I've seen on here, well I was wrong by about an 1/8" My straight hose connector was hitting the crank pulley. So I went to the local pseed shop and ended up spending twice as much as I would ordering online but at least I was able to see the stuff in person and make some measurements and get it right. had to have a couple 45*s to get around that.

And then I spent the next 3 hours trying to figure out the good way to do these AN fittings from Anfittingsdirect.com. What a pain, have to cut he stainless back from the PTFE hose to fit the collar on and then tighten the fitting. I was able to make my drain line finally. I think I can get more angle out of it if I adjust the angle down at the pan.

I'm also going to need to figure out hwo well a wastegate will fit on front of the manifold. I haven't seen another thread yet with a person using the stainless manifold and a wastegate on the front of it. Obviously the heater core hoses need to be modified, it also will be close to the turbo drain.

And then I spent the next 3 hours trying to figure out the good way to do these AN fittings from Anfittingsdirect.com. What a pain, have to cut he stainless back from the PTFE hose to fit the collar on and then tighten the fitting. I was able to make my drain line finally. I think I can get more angle out of it if I adjust the angle down at the pan.

I'm also going to need to figure out hwo well a wastegate will fit on front of the manifold. I haven't seen another thread yet with a person using the stainless manifold and a wastegate on the front of it. Obviously the heater core hoses need to be modified, it also will be close to the turbo drain.

#25

Launching!

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: Minnesota

Posts: 299

Likes: 0

Received 0 Likes

on

0 Posts

That's kind of what I'm thinking I will do for the heater lines, run them out over the passenger fender like you always see in the muscle cars.

I've seen in some posts by Trick yesterday while I was searching that he mentioned his kits just block the port and use a WG on the crossover. Why have it in the manifold if it's not used?

I am also wondering if just the one 38mm wastegate will be enough to run under 10psi with the 402? It's possible I may need to run one in the crossover and have two of them on the system. I haven't seen another thread yet where someone has used this cast manifold. Has anyone else seen something I can check out for some ideas?

I've seen in some posts by Trick yesterday while I was searching that he mentioned his kits just block the port and use a WG on the crossover. Why have it in the manifold if it's not used?

I am also wondering if just the one 38mm wastegate will be enough to run under 10psi with the 402? It's possible I may need to run one in the crossover and have two of them on the system. I haven't seen another thread yet where someone has used this cast manifold. Has anyone else seen something I can check out for some ideas?

#29

Launching!

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: Minnesota

Posts: 299

Likes: 0

Received 0 Likes

on

0 Posts

Yeah, the front wastegate location seems pretty odd. Especially if he doesn't even sell the complete hot side kits that utilize it.

There are other places to put the drain. I've seen many people do it on the passenger side of the pan. I decided to go in the front because of space. The passenger side is busy enough with the manifold, a down pipe, wastegate pipe and wideband already planning to be put in over there. When I drilled the front oil pan last year, I looked at pics and basically made a good guess on where to put it and it happened to be 1/4" too far left. The straight fitting on planned to use is way bigger than I expected.

What part of the drain don't you like Choda? The stupid amount of fittings or the routing?

There are other places to put the drain. I've seen many people do it on the passenger side of the pan. I decided to go in the front because of space. The passenger side is busy enough with the manifold, a down pipe, wastegate pipe and wideband already planning to be put in over there. When I drilled the front oil pan last year, I looked at pics and basically made a good guess on where to put it and it happened to be 1/4" too far left. The straight fitting on planned to use is way bigger than I expected.

What part of the drain don't you like Choda? The stupid amount of fittings or the routing?