Custom Fabricated Dual 3" Exhaust

#1

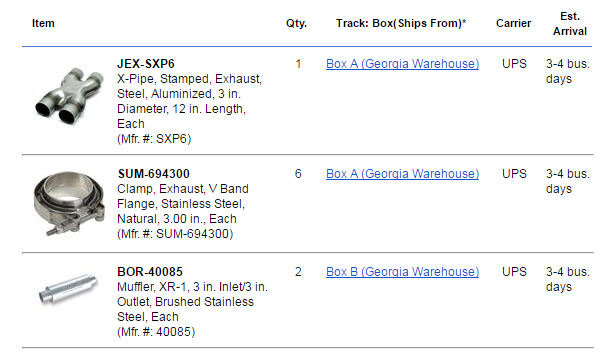

My truck, 2005 single cab 4.8, developed an embarrassing rattle in the exhaust system. I crawled the truck middle to back (as this was where the sound appeared to be) and didn't find anything. I foolishly/excitedly assumed the Flowmaster broke a baffle and that was the noise. It turns out one of the heat shields on the driver exhaust manifold lost a bolt head and was likely the culprit. I didnít realize this until they were removed, so it was a little late to turn back. A few weeks before, I made a couple orders to speed shops for parts to scratch build the whole thing. I wanted to try a different brand of muffler and went with Borla XR1. I collected some Texas Speed long tube headers with off road y-pipe, x-pipe, 3" universal exhaust pipe kit, v-band flanges, and loud mufflers. I have roughly 30 hours in this project. I have a small garage, no lift, and no air compressor. As such, I had to man handle this whole thing. The main tools were basic ratchet/wrench set, angle grinder, chop saw, oxy-acetylene torch, and decent MIG welder. When I moved into this house I epoxy coated the garage floor. This makes working on the truck far easier. Lay down, grab a piece of tire/frame/whatever and it takes little effort to slide into place.

New Parts

The schedule was to follow as below:

1. Friday-Disassembly

2. Saturday-Pipe Fabrication-Mid Pipes

3. Sunday-Pipe Fabrication-To Rear Bumper

What actually happened:

1. Friday-My buddy Tyler calls me up on my way home saying he had an engine light and Auto Zone said it was a misfire caused by spark plugs. Friday nights plans went to hell. For anyone who cares, Dodge 4.7 Hemiís have 2 plugs per cylinder. The top most spark plugs have a coil which bolts directly to them. The rubber boot which attaches to the plug likes to break off into the head. Fishing that crap out took a long time.

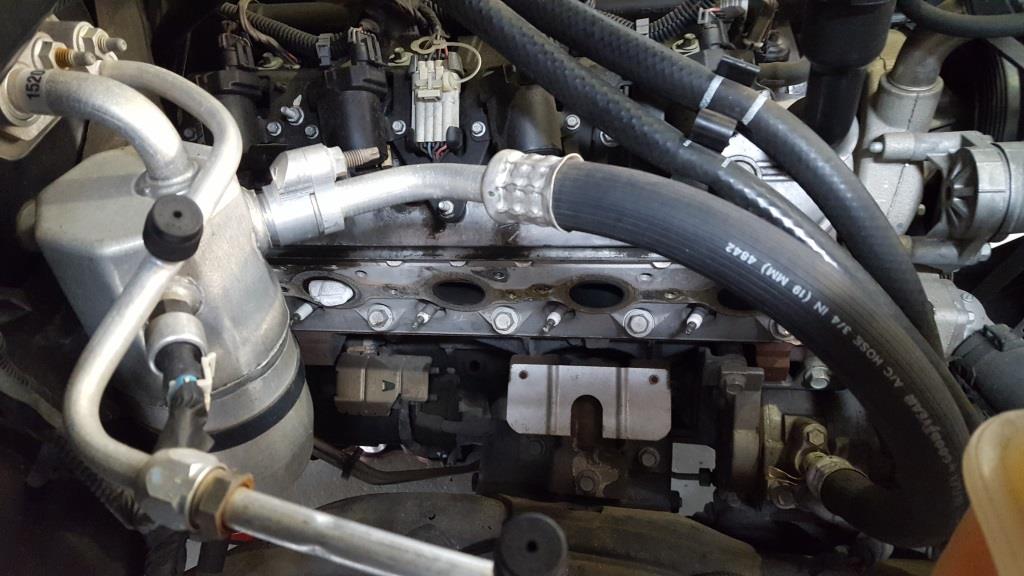

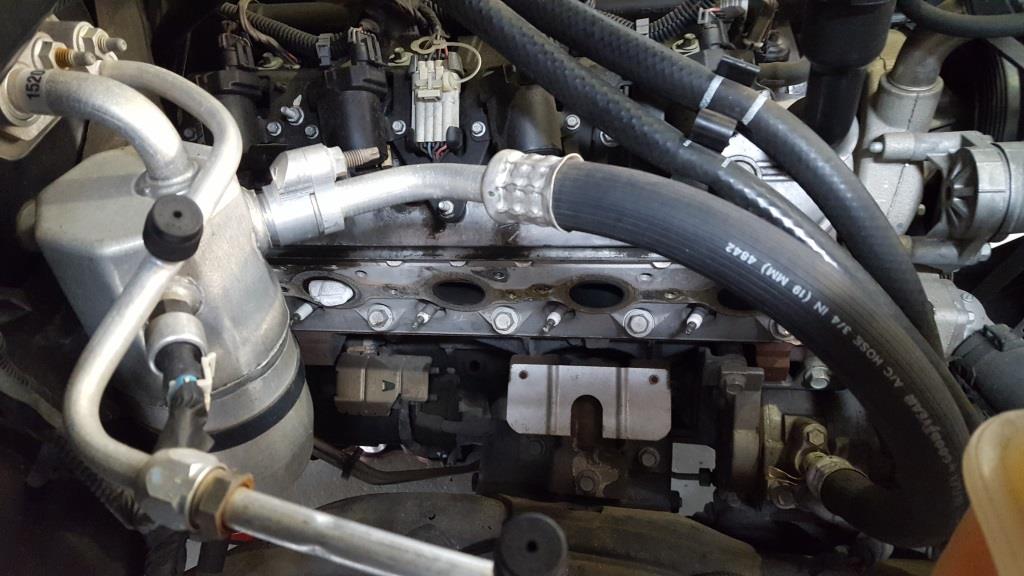

2. Saturday-Woke up early and started disassembly. This sucked. I keep my truck clean and it has lived in Texas for all of its life. The collector bolts had to be heated with the oxy-torch to approach loose. Header install was equally grueling. I had 2 broken bolts, but luckily they were the driver front and passenger rear. I heated them with the torch until red, let them cool down a little, and fought those bastards out with vise grips. My original plan was to weld v-bands to the collectors. Luckily I decided to test fit the headers before welding the flanges onto the collector. This saved my ***. The passenger side header had zero clearance between the head, firewall, and frame rail. I took off the oil fill tube, coil pack, starter, and had to loosen the A/C accumulator to shoe horn the header into place. There is zero chance I would have been able to install that side with the engine in place.

Mid Pipe fabrication was equally terrible. I got everything tacked between the headers and x-pipe like I wanted. For those paying attention, I did use part of the Texas Speed y-Pipe. I chopped it right at the merge and used some pie cuts to meet up with the x-Pipe. 30 seconds into finish welding I realized the welder ran out of wire. After acquiring more wire, I proceeded to weld the v-band flanges too close together at the x-Pipe such that the clamps wouldn't have enough room side by side. I then realize I didn't buy cut-off discs when I was purchasing welding wire. So pissed. I decided I would call it an "early" night and crash.

3. Sunday-I woke up early and purchased cut-off discs. I cut the flanges off the x-pipe and came up with plan B for how to gracefully separate 17 feet of exhaust for finish welding/service/etc. About 10:30am I realized there is no GD way I will get this 100% done. The focus now came down to a number of small details. Re-installed the headers w/ gaskets, wideband bung, spark plugs, wires, pass. coil pack, starter, steering shaft, cross member for the 27th time, flash a calibration, etc. etc. At one time I was foolish enough to think I could reuse the stock hangers. Not in enough time to drive to work the next day. So now the focus was on getting the truck running cause that would be a huge success at this point. All the details went together without too much effort. Except for drilling the hole for the wideband bung. Drilling holes in stainless sucks. I should have driven to my folks and used the drill press. That took longer than I care to admit. Installing the starter is now a much larger pain in the ***. The headers are really close to everything on the passenger side. Nothing is touching anywhere, but there will be some header wrap in the future.

Long story stupid, the truck fired right up and sounded a lot different. A nice deep rumble. Keep in mind, at this point its configuration was headers to x-pipe to mufflers. Once the exhaust gets back to the bumper it will sound even better. A special side note for me, this was my first time using HP Tuners to do anything to the truck. I was pretty worried for no good reason. I set all O2 sensor 2 DTCs to no error reported and COT to disabled. I clicked write calibration and that was it. As mentioned previously, I thought I could use the stock hangers. I didnít purchase hangers so at this point in the day I thought I would end on a positive note and drive the Camaro to work Monday.

Tuesday I installed some hangers and buttoned up the last bunch of crap to take it for a blast. At speed, off the throttle is very quiet. Much more so than the last exhaust. When you are to the floor it is a riot. It's a damn shame it doesn't accelerate as aggressively as it sounds. I have plans for that, but for now I'm excited that it doesn't rattle like I don't know how to fix things.

After driving the truck for a few days I hated this exhaust. It droned like crazy and had some ugly rasp anytime on the throttle. I know this was due mostly because the exhaust ends at the mufflers with no turn downs. However I was curious how this would sound once finished. Cause at this point it sounded like crap.

Weekend 2

Sunday I started running pipe from the mufflers to up over the axle. This was a pain in the butt. There are lots of bends necessary for bumper exit exhaust. I only had so many bends to work with from the universal kit, so I was trying my best to conserve them. The extra pipe made it sound so much better. The drone was gone and it was much less aggressive sounding on the gas. I was not in love, but this made me very confident that once the exhaust got to the bumper it would sound great.

New Parts

The schedule was to follow as below:

1. Friday-Disassembly

2. Saturday-Pipe Fabrication-Mid Pipes

3. Sunday-Pipe Fabrication-To Rear Bumper

What actually happened:

1. Friday-My buddy Tyler calls me up on my way home saying he had an engine light and Auto Zone said it was a misfire caused by spark plugs. Friday nights plans went to hell. For anyone who cares, Dodge 4.7 Hemiís have 2 plugs per cylinder. The top most spark plugs have a coil which bolts directly to them. The rubber boot which attaches to the plug likes to break off into the head. Fishing that crap out took a long time.

2. Saturday-Woke up early and started disassembly. This sucked. I keep my truck clean and it has lived in Texas for all of its life. The collector bolts had to be heated with the oxy-torch to approach loose. Header install was equally grueling. I had 2 broken bolts, but luckily they were the driver front and passenger rear. I heated them with the torch until red, let them cool down a little, and fought those bastards out with vise grips. My original plan was to weld v-bands to the collectors. Luckily I decided to test fit the headers before welding the flanges onto the collector. This saved my ***. The passenger side header had zero clearance between the head, firewall, and frame rail. I took off the oil fill tube, coil pack, starter, and had to loosen the A/C accumulator to shoe horn the header into place. There is zero chance I would have been able to install that side with the engine in place.

Mid Pipe fabrication was equally terrible. I got everything tacked between the headers and x-pipe like I wanted. For those paying attention, I did use part of the Texas Speed y-Pipe. I chopped it right at the merge and used some pie cuts to meet up with the x-Pipe. 30 seconds into finish welding I realized the welder ran out of wire. After acquiring more wire, I proceeded to weld the v-band flanges too close together at the x-Pipe such that the clamps wouldn't have enough room side by side. I then realize I didn't buy cut-off discs when I was purchasing welding wire. So pissed. I decided I would call it an "early" night and crash.

3. Sunday-I woke up early and purchased cut-off discs. I cut the flanges off the x-pipe and came up with plan B for how to gracefully separate 17 feet of exhaust for finish welding/service/etc. About 10:30am I realized there is no GD way I will get this 100% done. The focus now came down to a number of small details. Re-installed the headers w/ gaskets, wideband bung, spark plugs, wires, pass. coil pack, starter, steering shaft, cross member for the 27th time, flash a calibration, etc. etc. At one time I was foolish enough to think I could reuse the stock hangers. Not in enough time to drive to work the next day. So now the focus was on getting the truck running cause that would be a huge success at this point. All the details went together without too much effort. Except for drilling the hole for the wideband bung. Drilling holes in stainless sucks. I should have driven to my folks and used the drill press. That took longer than I care to admit. Installing the starter is now a much larger pain in the ***. The headers are really close to everything on the passenger side. Nothing is touching anywhere, but there will be some header wrap in the future.

Long story stupid, the truck fired right up and sounded a lot different. A nice deep rumble. Keep in mind, at this point its configuration was headers to x-pipe to mufflers. Once the exhaust gets back to the bumper it will sound even better. A special side note for me, this was my first time using HP Tuners to do anything to the truck. I was pretty worried for no good reason. I set all O2 sensor 2 DTCs to no error reported and COT to disabled. I clicked write calibration and that was it. As mentioned previously, I thought I could use the stock hangers. I didnít purchase hangers so at this point in the day I thought I would end on a positive note and drive the Camaro to work Monday.

Tuesday I installed some hangers and buttoned up the last bunch of crap to take it for a blast. At speed, off the throttle is very quiet. Much more so than the last exhaust. When you are to the floor it is a riot. It's a damn shame it doesn't accelerate as aggressively as it sounds. I have plans for that, but for now I'm excited that it doesn't rattle like I don't know how to fix things.

After driving the truck for a few days I hated this exhaust. It droned like crazy and had some ugly rasp anytime on the throttle. I know this was due mostly because the exhaust ends at the mufflers with no turn downs. However I was curious how this would sound once finished. Cause at this point it sounded like crap.

Weekend 2

Sunday I started running pipe from the mufflers to up over the axle. This was a pain in the butt. There are lots of bends necessary for bumper exit exhaust. I only had so many bends to work with from the universal kit, so I was trying my best to conserve them. The extra pipe made it sound so much better. The drone was gone and it was much less aggressive sounding on the gas. I was not in love, but this made me very confident that once the exhaust got to the bumper it would sound great.

#2

Weekend 3

I started the last section of the exhaust. I needed to add the final set of v-bands and run pipe back to the bumper. I welded some straight pipe to the tips so they could be set on jack stands and positioned correctly. The driver side fell together. The passenger side took a good bit longer.

In the end I am pleased with myself. The test drive was great. It sounds fantastic. When it fires up, it sounds different than before. Cruising around it sounds nice and civilized. WOT sounds great! The cabin volume at 70 mph is less than with the flowmaster. I couldnít be happier. This was a bunch of work. The truck was at ride height throughout the entire process. If I had a lift, cold saw, and tig I would be dangerous!

Tools

The big winners were the oxy torch, MIG welder, angle grinder, and chop saw. I purchased a nice Evolution chop saw blade that did pretty well. I doubt it has many good cuts before a sharpening is in order. It cut much more straight than a standard friction blade. The burr left at the bottom was a real pain though. I learned a hard lesson that the burr needs to be removed. I got lazy on weekend 2 and that lead to many contaminated welds.

V-Bands

This was my first experience with v-bands. I have read stories about galling on the clamp threads. I coated the bolt threads with anti-sieze before I tightened the clamps. I have had the clamps on/off several times and thus far the stainless fasteners havenít galled. I cleaned and put a fresh bead of high temp RTV on the flanges each time I assembled them. Either Iím very lucky or not tightening the crap out of the clamps was the ticket.

Driveability

I lost a good bit of torque in the low RPMs. This is understandable since dual 3Ē is way overkill on a stock 4.8L. However, the upper RPMs are much more fun. I need a Procharger so bad. In an effort to be smart about this build, I will be overhauling the rear end before the power adder gets ordered. I have an ISKY cam I purchased years ago, but am not too interested in installing it before I get a new short block The current 4.8L has about 167,000 on it and Iím not sure how I feel about putting a cam and blower on this motor. I have to imagine it would leave a lot to be desired. I have been eyeballing a TMS 370Ē for years, but never manage to pull the trigger. I will baby step this thing through a rear end and front suspension rebuild. At that point I will probably have my mind made up between short block and blower. As for the 4L60, I have a new Jakes 4L80 transmission that has been sitting in my house for 3 years. I figure once the drive line is sorted out, I will be ready for fun. If you have any questions, fire away.

I started the last section of the exhaust. I needed to add the final set of v-bands and run pipe back to the bumper. I welded some straight pipe to the tips so they could be set on jack stands and positioned correctly. The driver side fell together. The passenger side took a good bit longer.

In the end I am pleased with myself. The test drive was great. It sounds fantastic. When it fires up, it sounds different than before. Cruising around it sounds nice and civilized. WOT sounds great! The cabin volume at 70 mph is less than with the flowmaster. I couldnít be happier. This was a bunch of work. The truck was at ride height throughout the entire process. If I had a lift, cold saw, and tig I would be dangerous!

Tools

The big winners were the oxy torch, MIG welder, angle grinder, and chop saw. I purchased a nice Evolution chop saw blade that did pretty well. I doubt it has many good cuts before a sharpening is in order. It cut much more straight than a standard friction blade. The burr left at the bottom was a real pain though. I learned a hard lesson that the burr needs to be removed. I got lazy on weekend 2 and that lead to many contaminated welds.

V-Bands

This was my first experience with v-bands. I have read stories about galling on the clamp threads. I coated the bolt threads with anti-sieze before I tightened the clamps. I have had the clamps on/off several times and thus far the stainless fasteners havenít galled. I cleaned and put a fresh bead of high temp RTV on the flanges each time I assembled them. Either Iím very lucky or not tightening the crap out of the clamps was the ticket.

Driveability

I lost a good bit of torque in the low RPMs. This is understandable since dual 3Ē is way overkill on a stock 4.8L. However, the upper RPMs are much more fun. I need a Procharger so bad. In an effort to be smart about this build, I will be overhauling the rear end before the power adder gets ordered. I have an ISKY cam I purchased years ago, but am not too interested in installing it before I get a new short block The current 4.8L has about 167,000 on it and Iím not sure how I feel about putting a cam and blower on this motor. I have to imagine it would leave a lot to be desired. I have been eyeballing a TMS 370Ē for years, but never manage to pull the trigger. I will baby step this thing through a rear end and front suspension rebuild. At that point I will probably have my mind made up between short block and blower. As for the 4L60, I have a new Jakes 4L80 transmission that has been sitting in my house for 3 years. I figure once the drive line is sorted out, I will be ready for fun. If you have any questions, fire away.

#6

nice job

also interested in sound clip

also interested in sound clip

#8

GoPro video. The microphone is damn sensitive on this thing, so it is quite boomy. I haven't uploaded videos to the forum yet, so lets see if this works.

<iframe width="560" height="315" src="https://www.youtube.com/embed/vSfRv15TJEg" frameborder="0" allowfullscreen></iframe>

<iframe width="560" height="315" src="https://www.youtube.com/embed/vSfRv15TJEg" frameborder="0" allowfullscreen></iframe>