Twins and not what u'r thinking. hint TVS 3800.

#122

TECH Addict

iTrader: (7)

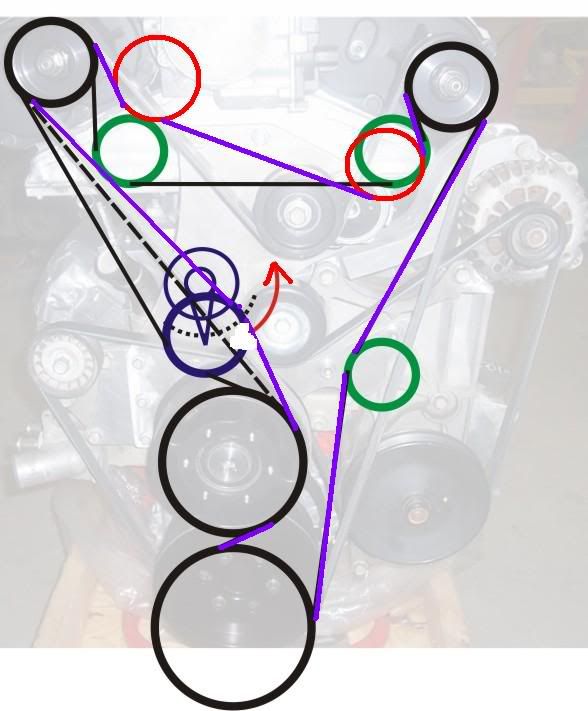

In this first diagram the tensioner stays in the original location, but clocked a bit counterclockwise from where it sits now. This is one possible solution for routing the belt that would put it after the two superchargers. The green circle is a smooth-groove idler pulley and the blue with the dotted line is the belt tensioner, applying tension counter clockwise. It's difficult to tell from the photo perspective, but I think the belt would clear the throttle body this way. This arrangement has slightly better wrap on the pulleys than the current configuration.

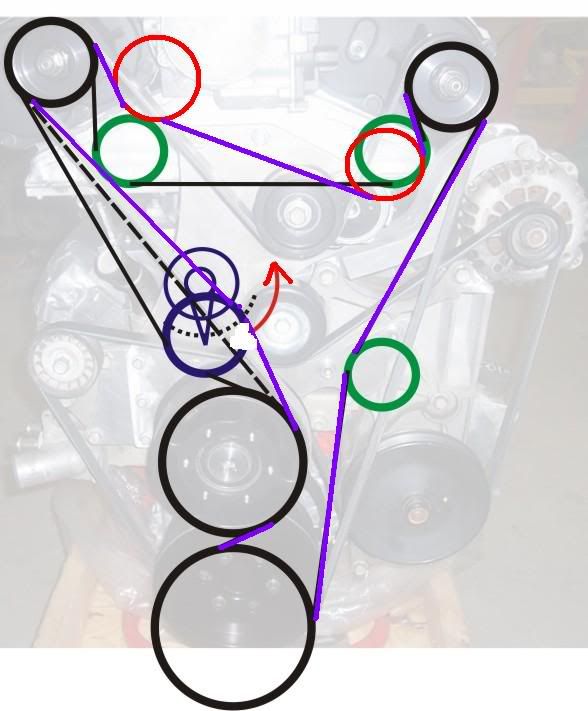

This second diagram is more optimal for a few reasons, in my opinion:

1 - The distance between the crank pulley and driver-side supercharger is stabilized by an idler pulley. Superchargers pulse in their rotation and the idler pulley will stabilize harmonic vibration in the long belt path.

2 - The two upper smooth-faced idler pulleys provide better wrap around the superchargers while still providing the throttle body clearance from the belt.

3 - The tensioner is after the two high-load driven devices. (note it applies tension clockwise, opposite from the current tensioner, and is a grooved pulley instead of smooth)

4 - The tensioner cannot be overextended by reverse-torque on the belt. During rapid deceleration, such as following a shift, the inertial energy of the large rotating masses in the superchargers will actually overspin the crank and belt tension will be in the opposite direction from normal. This tends to bottom out the tensioner, hyper-compressing it. Since tensioners are not designed to hold up against this much load, they generally break off or the travel-stop ear busts off the tensioner housing. I've also seen the locating pin be sheared off the housing. In either case - damage. By locating the belt tensioner in a path were a fully-tensioned belt cannot over-compress the tensioner, damage to it is prevented and the torque needed to slow down the driven accessories is transferred - the belt is less likely to be thrown off in the process. In the diagram below, the dotted line shows where the belt would be fully taught, the black line is an approximation of the normal path taken with tensioner pressure on it. For best results, the smallest belt that can be put on will be best here, so the tensioner travel is minimized providing more travel to take up the slack caused by belt stretch under high load or rapid acceleration. Also worth mentioning, the less "wrap" on the tensioner pulley, the more leverage force the spring can exert on the belt to keep it tight. More wrap provides greater slack take-up ability, but less tension. With the superchargers you need a balance that favors high belt tension and enough travel to take up the huge amount of slack created by belt stretch under load.

5 - This layout is more symetrical than the first graphic. The design for the belt path you guys came up with is visually stunning - great symmetry and the two pulleys have nearly the same amount of belt wrap on them, I think keeping the tensioner in your location would detract from the theme of symmetry you have right now. In my opinion, it would be worth your trouble to revise the 8-rib belt path to something incorporating these considerations.

That manifold and induction really is a work of art. I wish I had the means to fabricate like that...

This second diagram is more optimal for a few reasons, in my opinion:

1 - The distance between the crank pulley and driver-side supercharger is stabilized by an idler pulley. Superchargers pulse in their rotation and the idler pulley will stabilize harmonic vibration in the long belt path.

2 - The two upper smooth-faced idler pulleys provide better wrap around the superchargers while still providing the throttle body clearance from the belt.

3 - The tensioner is after the two high-load driven devices. (note it applies tension clockwise, opposite from the current tensioner, and is a grooved pulley instead of smooth)

4 - The tensioner cannot be overextended by reverse-torque on the belt. During rapid deceleration, such as following a shift, the inertial energy of the large rotating masses in the superchargers will actually overspin the crank and belt tension will be in the opposite direction from normal. This tends to bottom out the tensioner, hyper-compressing it. Since tensioners are not designed to hold up against this much load, they generally break off or the travel-stop ear busts off the tensioner housing. I've also seen the locating pin be sheared off the housing. In either case - damage. By locating the belt tensioner in a path were a fully-tensioned belt cannot over-compress the tensioner, damage to it is prevented and the torque needed to slow down the driven accessories is transferred - the belt is less likely to be thrown off in the process. In the diagram below, the dotted line shows where the belt would be fully taught, the black line is an approximation of the normal path taken with tensioner pressure on it. For best results, the smallest belt that can be put on will be best here, so the tensioner travel is minimized providing more travel to take up the slack caused by belt stretch under high load or rapid acceleration. Also worth mentioning, the less "wrap" on the tensioner pulley, the more leverage force the spring can exert on the belt to keep it tight. More wrap provides greater slack take-up ability, but less tension. With the superchargers you need a balance that favors high belt tension and enough travel to take up the huge amount of slack created by belt stretch under load.

5 - This layout is more symetrical than the first graphic. The design for the belt path you guys came up with is visually stunning - great symmetry and the two pulleys have nearly the same amount of belt wrap on them, I think keeping the tensioner in your location would detract from the theme of symmetry you have right now. In my opinion, it would be worth your trouble to revise the 8-rib belt path to something incorporating these considerations.

That manifold and induction really is a work of art. I wish I had the means to fabricate like that...

#124

TECH Addict

iTrader: (7)

This is more like what I am seeing after taking a closer look at things. The tensioner unwinds counterclockwise. The pass side idler might be able to come down a little if I can get the tensioner as low as it is in the sketch. TBs can always stick through the hood like dual carbs.

In your drawing the tensioner will have to be flipped top to bottom due to the direction of unwinding, so then the tensioner pulley will end up approximately halfway between the WP and blower pulleys. Seems like that might tend to decrease belt wrap on the blower pulley under load.

In your drawing the tensioner will have to be flipped top to bottom due to the direction of unwinding, so then the tensioner pulley will end up approximately halfway between the WP and blower pulleys. Seems like that might tend to decrease belt wrap on the blower pulley under load.

#125

TECH Fanatic

iTrader: (1)

It might be possible to run it that way if you can figure out how to clear the throttle body. The passenger side idler does not need to be so high up, there's nothing to mount it to there also.

The tensioner will also need to be far enough from the oem 6-rip idler to clear.

Even pushing the belt in the direction that unraps the second supercharger still wraps more that the present path.

Edit: be sure the tensioner is located where it can take up all the slack from the stretching belt. If it's pushing near the center of a long run the angles are not going to give it very much slack take-up ability. This is why I located it to throw right next to the free-spinning waterpump pulley.

The tensioner will also need to be far enough from the oem 6-rip idler to clear.

Even pushing the belt in the direction that unraps the second supercharger still wraps more that the present path.

Edit: be sure the tensioner is located where it can take up all the slack from the stretching belt. If it's pushing near the center of a long run the angles are not going to give it very much slack take-up ability. This is why I located it to throw right next to the free-spinning waterpump pulley.

#126

This is more like what I am seeing after taking a closer look at things. The tensioner unwinds counterclockwise. The pass side idler might be able to come down a little if I can get the tensioner as low as it is in the sketch. TBs can always stick through the hood like dual carbs.

In your drawing the tensioner will have to be flipped top to bottom due to the direction of unwinding, so then the tensioner pulley will end up approximately halfway between the WP and blower pulleys. Seems like that might tend to decrease belt wrap on the blower pulley under load.

In your drawing the tensioner will have to be flipped top to bottom due to the direction of unwinding, so then the tensioner pulley will end up approximately halfway between the WP and blower pulleys. Seems like that might tend to decrease belt wrap on the blower pulley under load.

#128

TECH Addict

iTrader: (7)

This is what I was looking at for a mock up. There is a little more belt wrap when the tensioner is engaged(its just hanging loose in the pic) and the lower drivers side idler is installed.

This tensioner doesn't have very much travel though. How much will the belt stretch under load? If I use the Radix kit, long arm tensioner it would have to mount right where the rad hose is so that it doesn't interfere with the belt path.

Edit: By the way, those are 3.0 blower pulleys, I managed to get hold of some 3.4s. Should keep the blowers in their sweet spot. My original calculations called for 3.6s.

This tensioner doesn't have very much travel though. How much will the belt stretch under load? If I use the Radix kit, long arm tensioner it would have to mount right where the rad hose is so that it doesn't interfere with the belt path.

Edit: By the way, those are 3.0 blower pulleys, I managed to get hold of some 3.4s. Should keep the blowers in their sweet spot. My original calculations called for 3.6s.

Last edited by DrX; 04-20-2009 at 11:01 PM.

#129

I think that tensioner will be fine. Just set the belts tightness so you will have to slip it over the water pump pulley last. That is the only smooth pulley not wasting tesioner movment to get the belt on. The rotation of your mounting location on the tensioner will help or hurt the tightness as well.

I had problems with the long arm stuff I found local as far as the spacing was concerned. The local ones kept hanging the idler way too far forward.

I had problems with the long arm stuff I found local as far as the spacing was concerned. The local ones kept hanging the idler way too far forward.

. Watch your fingers though,

. Watch your fingers though,