reluctor wheel install

#1

TECH Fanatic

Thread Starter

iTrader: (5)

Join Date: Nov 2005

Location: Portsmouth, VA

Posts: 1,152

Likes: 0

Received 0 Likes

on

0 Posts

Does anyone have pictures of a properly installed reluctor wheel? I think mine kay be backwards or clocked wrong amd I want to verify before I pull the engine back out.

#2

TECH Junkie

iTrader: (9)

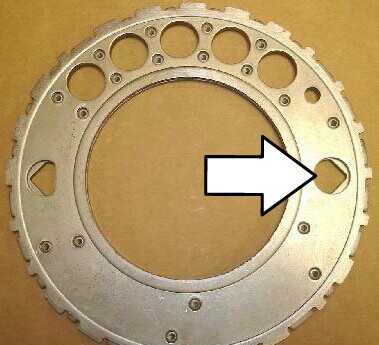

It is going to be hard to tell from a pic. Does the ring line up in the center of the crank sensor hole? There are 2 pieces that come together to make the ring. There is a specific area on the ring where you can actually tell by feeling around in there with a wire. One half will be rounded and the other will come to a point. Let me see if I can find a pic for you to better clarify what I mean.

Meanwhile if you see this can you explain what symptoms you are having. Improper air gap for the crank sensor can cause spark issues.

Meanwhile if you see this can you explain what symptoms you are having. Improper air gap for the crank sensor can cause spark issues.

#4

TECH Fanatic

Thread Starter

iTrader: (5)

Join Date: Nov 2005

Location: Portsmouth, VA

Posts: 1,152

Likes: 0

Received 0 Likes

on

0 Posts

anytime the engine gets about 2k it pings and misfires. it gave me a p0336. it has never died on me while driving. the dyno tuner couldnt get the engine to take ANY timing. he thinks it may be on backwards. i was going to pull the pan and windage tray and look this weekend. the only other thing that i can think of is i advanced the cam to much.

#6

TECH Fanatic

Thread Starter

iTrader: (5)

Join Date: Nov 2005

Location: Portsmouth, VA

Posts: 1,152

Likes: 0

Received 0 Likes

on

0 Posts

i blame you for this. you and your bad news telling me my compression is not to high for pump gas. could have had good news for me and made it easy but noooooooo. i hope its the cam at this point but i hate the thought that i messed up an install.

#7

TECH Junkie

iTrader: (9)

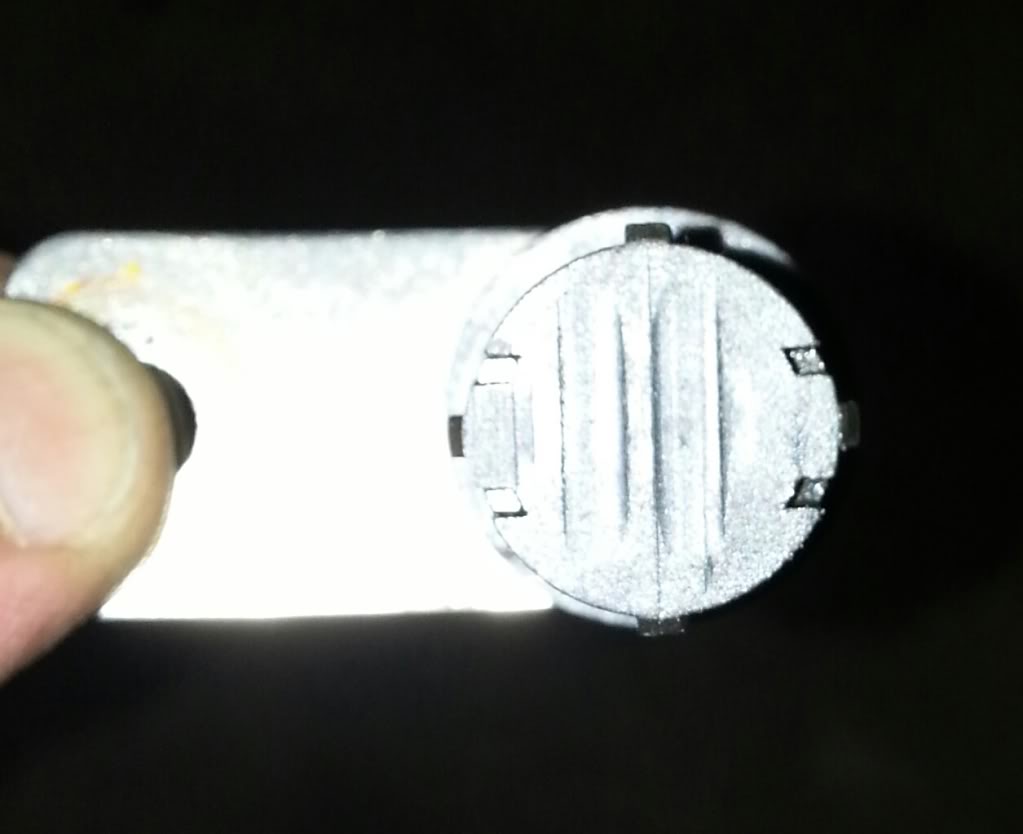

Mine did the same thing and it was my air gap for the crank sensor. I believe you should be shooting for .020 air gap from the ring. I heard somewhere that the older blocks (mine is a 99) dont leave enough clearance, and can hold the sensor too close to the ring causing misfires. My sensor actually had grooves in it from the ring hitting it. I measured the grooves at .009, so I added a .030 washer under the bracket mounting it to the block. (.030-.009 put me at .021 air gap). I have not had a problem since.