LS2 cam in 4.8L?

#11

TECH Fanatic

Join Date: Oct 2005

Location: Woodstock Ontario Canada

Posts: 1,379

Likes: 0

Received 0 Likes

on

0 Posts

Here are dyno testing comparing all teh GEN 3/4 OEM roller cams.

LS Cam Test Comparison - Car Craft Magazine All Pages

peace

Hog

LS Cam Test Comparison - Car Craft Magazine All Pages

peace

Hog

#12

Here are dyno testing comparing all teh GEN 3/4 OEM roller cams.

LS Cam Test Comparison - Car Craft Magazine All Pages

peace

Hog

LS Cam Test Comparison - Car Craft Magazine All Pages

peace

Hog

#13

Starting prep for Cam removal, I think two 3/8" dia 18" long rods will hold the lifters up? How long are the LS motor cams? I very carefully finagled the charged condenser to the other side of the rad support, giving me 18" from the inside edge of the cam gear to the condenser..me hopes this is enough?

Hot damn the crank bolt was tough to remove, I hope I didn't twist the crank? E-brak on, in fourth gear, 24mm socket 1/2" drive breaker bar, three foot pipe, it mhttp://www.355nation.net/forum/images/editor/color.gifoved 1/2 turn, but was either twist in the crank, or clutch slipping. Heated hub with torch, tired 300lbs impact with 125psi of air, no go. wedged crowbar in hub spokes against a/c bracket, in forth gear, e-brake set, with heat, 4 foot bar, on breaker bar, leaned into it, heard snap, lost my foot drop tool, hit knee on bumper!! Try bolt still kinda tight hit, with impact, comes right out.

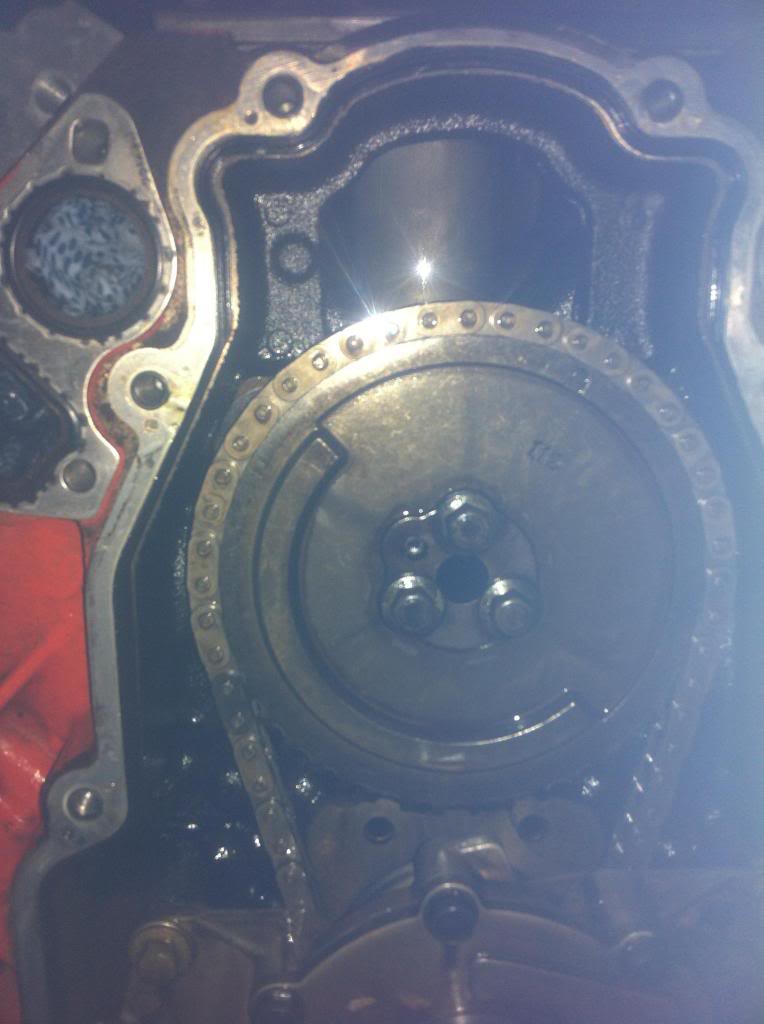

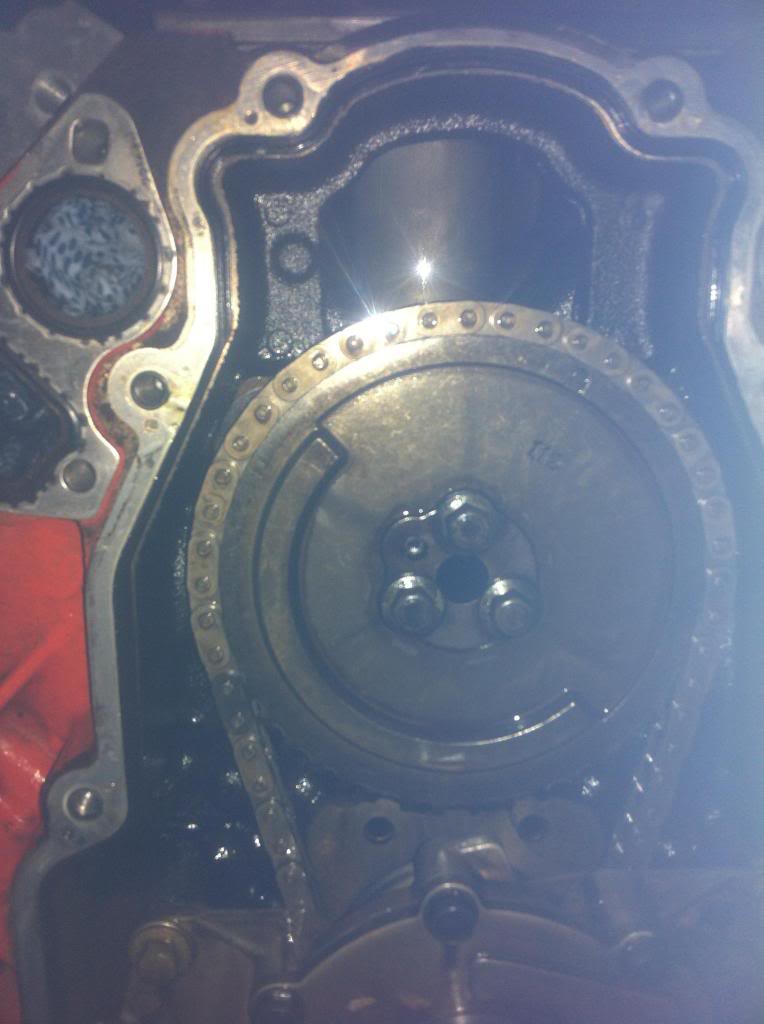

Canadian tire free lend a tool import balancer removal set. Worked but I needed, a loner extension, used a 9mm 1/4" drive socket, which got pressed slightly, into the end of the crank, thank god it came out, and no damage, bolt still goes all the way in! Puller was begging for mercy, stripped gears on 3.8" drive ratchet, then 1/2" drive ratchet, then used 1/2" drive breaker bar, on the puller, wow GM doesn't want the balancer to some off? Anyway, ounce that was off 15 min, and the front cover is off, sweet I already have the LS2 1x 3 bolt cam sprocket I need, thanks GM!

me waits on arrival of parts.

This would also be a Mild upgrade for you factory 5.3L 355 owners. a LS2 cam is very similar to the 5.3L HO Cam Gm offers! But would only work on a 09 Colorado factory V8, as far as I know the 2010 and up are VVT?

Hot damn the crank bolt was tough to remove, I hope I didn't twist the crank? E-brak on, in fourth gear, 24mm socket 1/2" drive breaker bar, three foot pipe, it mhttp://www.355nation.net/forum/images/editor/color.gifoved 1/2 turn, but was either twist in the crank, or clutch slipping. Heated hub with torch, tired 300lbs impact with 125psi of air, no go. wedged crowbar in hub spokes against a/c bracket, in forth gear, e-brake set, with heat, 4 foot bar, on breaker bar, leaned into it, heard snap, lost my foot drop tool, hit knee on bumper!! Try bolt still kinda tight hit, with impact, comes right out.

Canadian tire free lend a tool import balancer removal set. Worked but I needed, a loner extension, used a 9mm 1/4" drive socket, which got pressed slightly, into the end of the crank, thank god it came out, and no damage, bolt still goes all the way in! Puller was begging for mercy, stripped gears on 3.8" drive ratchet, then 1/2" drive ratchet, then used 1/2" drive breaker bar, on the puller, wow GM doesn't want the balancer to some off? Anyway, ounce that was off 15 min, and the front cover is off, sweet I already have the LS2 1x 3 bolt cam sprocket I need, thanks GM!

me waits on arrival of parts.

This would also be a Mild upgrade for you factory 5.3L 355 owners. a LS2 cam is very similar to the 5.3L HO Cam Gm offers! But would only work on a 09 Colorado factory V8, as far as I know the 2010 and up are VVT?

#14

Here is my springs and vavle spring tool! Tool was only 72.00 shipped from Amazon! and can compress two springs at a time, with the heads in place.

I'm a bit unsure of the springs, they were supposed to be GM springs, off Ebay, but came in a Zip lock bag? They look new, and here blue..lol? But are they LS2/LS6 springs?

Proform tool in action

LS Valve Spring Compressor by PROFORM - YouTube

I'm a bit unsure of the springs, they were supposed to be GM springs, off Ebay, but came in a Zip lock bag? They look new, and here blue..lol? But are they LS2/LS6 springs?

Proform tool in action

LS Valve Spring Compressor by PROFORM - YouTube

#15

TECH Fanatic

iTrader: (2)

You need 2 5/16 OAK wooden rods from home depot, etc. I would cut them to about 22". Also, with the 4.8, you can just bring the piston to top dead center rather then using compressed air or rope. The valve will not drop in, or atleast will not on the 4.8. The ls valve spring compressor is nice, and I needed it for my dual valve springs, but if your just replacing with singles, the cheapy tool from the auto part store for 10 bucks will work, and thing stronger like duals and it bends. I just did the cam and spring swap on my 03 4.8, and did not have to use compressed air. Just put a breaker bar on the crank bolt and watch for the valves to come all the way up. They drop a little, but not much at all.

#16

You need 2 5/16 OAK wooden rods from home depot, etc. I would cut them to about 22". Also, with the 4.8, you can just bring the piston to top dead center rather then using compressed air or rope. The valve will not drop in, or atleast will not on the 4.8. The ls valve spring compressor is nice, and I needed it for my dual valve springs, but if your just replacing with singles, the cheapy tool from the auto part store for 10 bucks will work, and thing stronger like duals and it bends. I just did the cam and spring swap on my 03 4.8, and did not have to use compressed air. Just put a breaker bar on the crank bolt and watch for the valves to come all the way up. They drop a little, but not much at all.

So bad news the LS2 base circle is different, I measured it before it went in.

LR4 base circle 1.552"

LS2 1.525" But I bet it is supposed to be 1.520" which is the same as the LS6.

Frustrating online spec said it was 1.552"So I wouldn't need new pushrods, wish I had just got the LS6 cam now!

Anyway what push rods do I need, seems to me they should be about 0.025" longer. So I'm thinking I need 16) 5/16" 0.80 pushrods 7.425" long? In a pinch can I use 7.45" long? Were is the best place to get them?

#17

Also on one of the lobes, on the side near the bottom, there was some pitting, which I polished, but it's still there, should I be worried about it? what would cause that? I hope it's not a temp hardening or coating issue? I hope it won't damage my lifter. I mean they are rollers, and it's not at the top were all the tension is.

How much slack in the chain is normal? Stock single roller, with about 50,000 miles. Should be hardly any slack, with that kind of millage? May they are that way new? I can wiggle the chain about 3/8" inch, and turn the cam gear 3/16"back and forth before the crank turns?

How much slack in the chain is normal? Stock single roller, with about 50,000 miles. Should be hardly any slack, with that kind of millage? May they are that way new? I can wiggle the chain about 3/8" inch, and turn the cam gear 3/16"back and forth before the crank turns?

#18

I hope I didn't ruin the hardening more buy trying to polish it with some 320 sand paper and wd-40, then burnish with stock brite pad, I lightly rubbed the hole cam, to remove a couple of specs of rust, and some oil tarnish.

The pitting is so minor, it is barley visible to the naked eye.

The pitting is so minor, it is barley visible to the naked eye.

#20

Yeah Thanks Hog, I'm interested to see what kinda power my little 4.8L will make?

Now for push rods, most people that do the LS6 cam swap, that has the same base circle as the LS2,whihc I have now found out. Use 7.45"push rods, but I think that's too long? One guy said is lifters bottomed out at that length and wouldn't fill; with oil.

I calculate that I need 1.552-1.520 base circle. = 0.032" so technically I need 7.432" rods? If my stock rods are exactly 7.4"

From what I can tell the stock ones are called 7.4" but actually measure 7.3180" So that plus 0.032" = 7.35"

Is this right? So I need 7.35" or true 7.4" would be close enough? Are the aftermarket push rods actually 7.4" exactly?

At the very least I could go with 7.425" but I think 7.45" is far too long?

Or am I missing something?

7.4"and 7.45"are about 30.00 cheaper to buy??? They are commonly .060 wall thinness, the 7.425" ones seem to be only 0.80" and cost 134.00 at least!

I'm so confused which rods to get?