Injector Flow vs Pump Flow

#11

Mod with training wheels

iTrader: (16)

Greg wrote up a nice article about injectors explaining low flow, high flow, fuel breakpoint, etc. I'll see if I can find it.

http://www.calibratedsuccess.com/***...%20Article.pdf

http://www.calibratedsuccess.com/***...%20Article.pdf

#15

TECH Veteran

iTrader: (5)

Nice informative write-up Richard.

Looks like I am right were I need to be with dual Walbro255 and Siemens 60's with a 1:1 fpr and 15psi of boost assuming no more than 400l/hr of fuel is needed. EDIT: Just looked at a recent track log and see a IDC of 95% at the top of first and 92% at the top of second so it looks like I am at the limit of my injectors and pumps.

Now we just need a spreadsheet showing fuel consumption per cfm air flow assuming max power afr for the specified fuel.

Looks like I am right were I need to be with dual Walbro255 and Siemens 60's with a 1:1 fpr and 15psi of boost assuming no more than 400l/hr of fuel is needed. EDIT: Just looked at a recent track log and see a IDC of 95% at the top of first and 92% at the top of second so it looks like I am at the limit of my injectors and pumps.

Now we just need a spreadsheet showing fuel consumption per cfm air flow assuming max power afr for the specified fuel.

Last edited by BigKID; 11-14-2012 at 10:04 PM.

#16

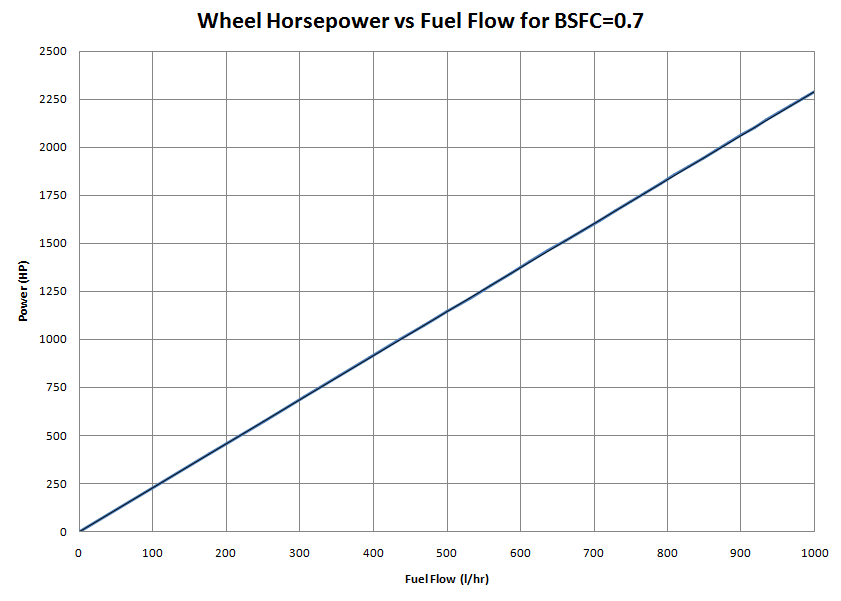

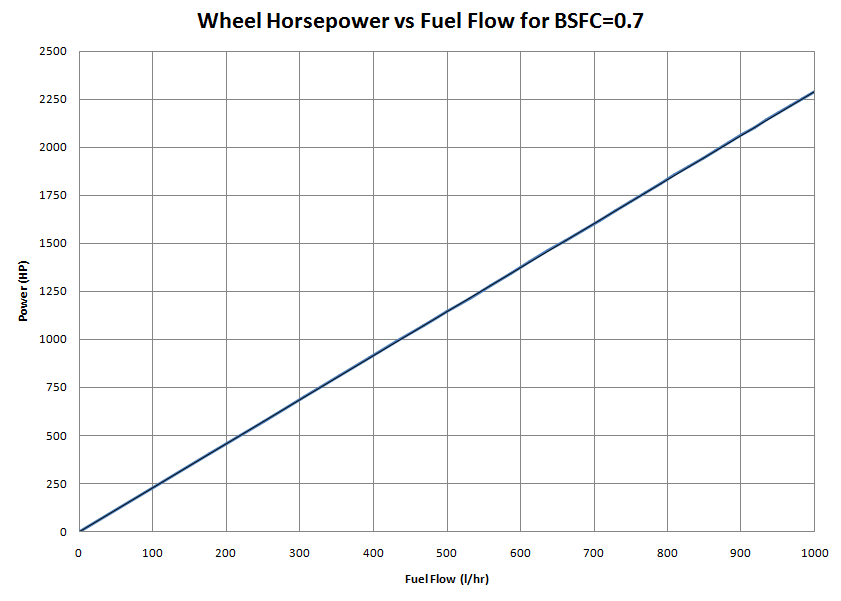

I just made this because I cant leave things alone

I plotted fuel flow against power produced using a BFSC of 0.7, which I think is a good estimate for these trucks. How you would use this is to find at what fuel flow your pump and injectors are equalized with whatever boost you are using (that flat line you draw from the injector line to the pump line, extend it all the way to the left to find fuel system flow), and look up what power level that corresponds to on this chart:

This is wheel horse power and assuming a BSFC of 0.7. This tells you what your fuel system is capable of supporting based on what you find from the right chart in the spreadsheet.

I plotted fuel flow against power produced using a BFSC of 0.7, which I think is a good estimate for these trucks. How you would use this is to find at what fuel flow your pump and injectors are equalized with whatever boost you are using (that flat line you draw from the injector line to the pump line, extend it all the way to the left to find fuel system flow), and look up what power level that corresponds to on this chart:

This is wheel horse power and assuming a BSFC of 0.7. This tells you what your fuel system is capable of supporting based on what you find from the right chart in the spreadsheet.

#17

13 Second Truck Club

iTrader: (1)

I just made this because I cant leave things alone

I plotted fuel flow against power produced using a BFSC of 0.7, which I think is a good estimate for these trucks. How you would use this is to find at what fuel flow your pump and injectors are equalized with whatever boost you are using (that flat line you draw from the injector line to the pump line, extend it all the way to the left to find fuel system flow), and look up what power level that corresponds to on this chart:

This is wheel horse power and assuming a BSFC of 0.7. This tells you what your fuel system is capable of supporting based on what you find from the right chart in the spreadsheet.

I plotted fuel flow against power produced using a BFSC of 0.7, which I think is a good estimate for these trucks. How you would use this is to find at what fuel flow your pump and injectors are equalized with whatever boost you are using (that flat line you draw from the injector line to the pump line, extend it all the way to the left to find fuel system flow), and look up what power level that corresponds to on this chart:

This is wheel horse power and assuming a BSFC of 0.7. This tells you what your fuel system is capable of supporting based on what you find from the right chart in the spreadsheet.

#18

13 Second Truck Club

iTrader: (1)

This also explains why I was able to push 10psi into my 6.0 and still get the AFR I needed on E85 with only a single 255 inline gravity fed, my injectors are 108@4 bar but I only had a single 255 with high flow fittings rated at 300lph, I was running my stock rail mounted regulator, but I didnt have a fuel pressure gauge, I think what was happening was I was losing fuel pressure but gaining fuel flow because my injectors were far from maxed out. Thanks for the info!

#19

I imagine if you use something like a BFSC of 1 it will get you close to an E85 rating, so basically the total amount of fuel in pounds per hour would also be the horespower rating. But again, im just guessing. So just shift the curve down 30%.