cast aluminum detail question

#28

TECH Veteran

iTrader: (5)

I'm not sure, but I think that you lose boost because it allows some of the air to spill out too soon. Like removing the bottom of a radiator fan shroud to simplify installation. The fan won't pull through the radiator as hard because the opening at the bottom is a big vacuum leak. Porting a blower's outlet used to be a popular mod because it is so simple and looks to be an obvious restriction, but I have read that you lose boost. Smoothing and rounding edges couldn't hurt (that would be where your porting analogy works), and anything at all that you can do on the inlet side is beneficial. Any pump of any type has increased efficiency with reduced inlet restriction. I reconfigured my blower's inlet housing to allow the use of a 102 mm throttle, it was a long time ago but I think it gave me two more psi boost.

#29

Makes sense. It already has the 102mm j tube and 102 Nick Williams throttle.

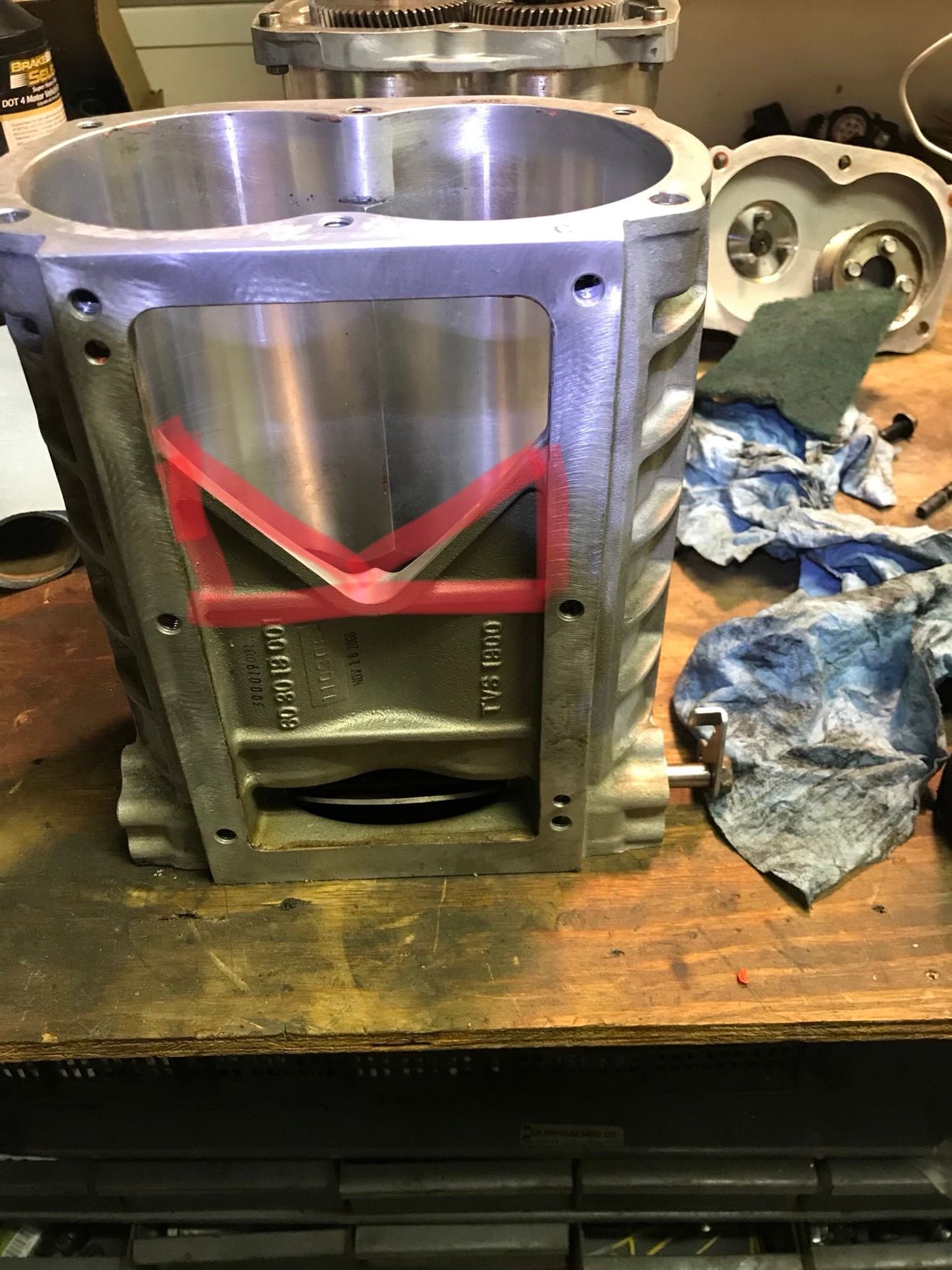

I put down the tools last night cuz i figured drilling, countersinking and tapping while drunk and tired wasnt the best plan. I just finished drilling the case and im happy with the results. I had to drill bigger than i wanted to get rid of the distortion but it came out great. I’ll go heavy with red loctite on those bolts along with some copper washers for extra insurance. I’m not worried.

i blasted everything with medium soda for the heavy oxidation followed by several soaks in aluminum brightener for the stains and oils on the outside and purple power for the gunk inside. Im happy with the results. I still plan to hit it with a high temp rattle can. Prep is the hard part. Need to hit up brian for the front mount accessories/tensioner and gaskets and it will fly back together.

I put down the tools last night cuz i figured drilling, countersinking and tapping while drunk and tired wasnt the best plan. I just finished drilling the case and im happy with the results. I had to drill bigger than i wanted to get rid of the distortion but it came out great. I’ll go heavy with red loctite on those bolts along with some copper washers for extra insurance. I’m not worried.

i blasted everything with medium soda for the heavy oxidation followed by several soaks in aluminum brightener for the stains and oils on the outside and purple power for the gunk inside. Im happy with the results. I still plan to hit it with a high temp rattle can. Prep is the hard part. Need to hit up brian for the front mount accessories/tensioner and gaskets and it will fly back together.

#30

makes children cry

iTrader: (5)

wow... context is key with that remark!

'losing boost' after porting the blower outlet to match the heads is due to the reduced outlet restriction (i.e., the air moves more freely from the rotors into the cylinders, which equates to less pressure being built up in the manifold). the reverse is true with your 102 inlet... you picked up boost because the blower's able to pull in more air to cram into the same usable manifold volume with the same engine consumption rate. the fact that you're drawing more air in with a larger inlet means that you were pulling vacuum on the old throttle body because it wasn't able to supply as much air as the blower was trying to use.

I'm not sure, but I think that you lose boost because it allows some of the air to spill out too soon. Like removing the bottom of a radiator fan shroud to simplify installation. The fan won't pull through the radiator as hard because the opening at the bottom is a big vacuum leak. Porting a blower's outlet used to be a popular mod because it is so simple and looks to be an obvious restriction, but I have read that you lose boost. Smoothing and rounding edges couldn't hurt (that would be where your porting analogy works), and anything at all that you can do on the inlet side is beneficial. Any pump of any type has increased efficiency with reduced inlet restriction. I reconfigured my blower's inlet housing to allow the use of a 102 mm throttle, it was a long time ago but I think it gave me two more psi boost.