intake bolt torque sequence?

#1

On The Tree

Thread Starter

iTrader: (2)

Join Date: Sep 2011

Location: northeast, ne

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

ive got my 02 tahoe tore down so i can replace my knock sensors. i am wondering if ther is a torque sequence when tighting the bolts ex( start in the middle and work my way to each end alternating sides) or what ? next is what coolant would you guys run? is ther such a thing as a relearn for the knock sensors? any thoughts would be great thanks..

#5

On The Tree

Thread Starter

iTrader: (2)

Join Date: Sep 2011

Location: northeast, ne

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

thanks guys. my parts should be comming this afternoon hope to have her back up and running tomorro nite with any luck.. just a thought a person may want to add the pic of the bolt sequence to the 6.0torque spec thread..

thanks again guys

thanks again guys

#6

#7

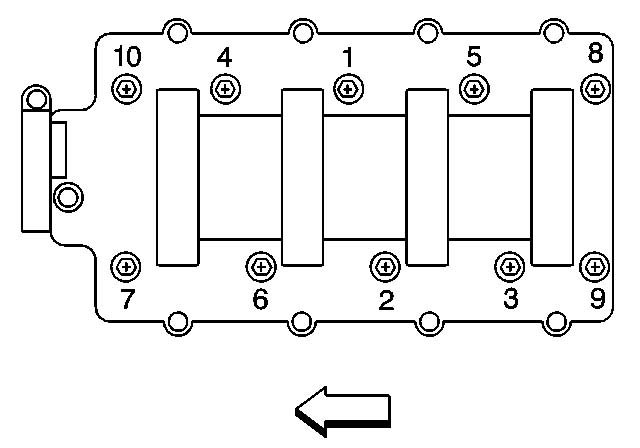

TECH Senior Member

iTrader: (27)

The correct way (per GM) is 2 passes, with a sequence similar or equivalent to the drawing above. I can't remember the torque specs or sequence off hand, but if you work on your vehicle a lot it's worth it to subscribe to ALLDATA, it has all this info. Also, you will need an inch-pound torque wrench to properly torque everything,

Trending Topics

#8

TECH Fanatic

Intake Manifold Bolt

First Pass in Sequence 5 Nm (44 inch lbs.)

Final Pass in Sequence 10 Nm (89 inch lbs.)

Intake Manifold Sight Shield Bolt (RPO LQ9 - 6.0L Engine) 9 Nm (80 inch lbs.)

Intake Manifold Sight Shield Bolt (4.8L, 5.3L, and RPO LQ4) 10 Nm (89 inch lbs.)

Intake Manifold Sight Shield Retainer Bolt 5 Nm (44 inch lbs.)

I personally tighten to 120in/lbs because I've encountered seal issues on machined heads.

First Pass in Sequence 5 Nm (44 inch lbs.)

Final Pass in Sequence 10 Nm (89 inch lbs.)

Intake Manifold Sight Shield Bolt (RPO LQ9 - 6.0L Engine) 9 Nm (80 inch lbs.)

Intake Manifold Sight Shield Bolt (4.8L, 5.3L, and RPO LQ4) 10 Nm (89 inch lbs.)

Intake Manifold Sight Shield Retainer Bolt 5 Nm (44 inch lbs.)

I personally tighten to 120in/lbs because I've encountered seal issues on machined heads.

Last edited by Suburbazine; 12-07-2011 at 05:41 PM.

#9

On The Tree

Thread Starter

iTrader: (2)

Join Date: Sep 2011

Location: northeast, ne

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

torque wrench isnt a prob for me most of the newer tractors i work on require inch lb torque setting for something on them..