Shimmy: Measured pinion angle - need some help now

#11

TECH Fanatic

Thread Starter

iTrader: (4)

Join Date: Jun 2003

Location: Chicago Burbs

Posts: 1,528

Likes: 0

Received 0 Likes

on

0 Posts

You beat me to it, I just posted in the other thread that I assumed the angle of the pinion didn't change when doing the shackle, but what you are showing makes sense, I would need fat end backward.

My problem still is that my pinion still points at a greater angle upward than my DS, so I still have a + pinion when all the reading I've done says it should be 0 or negative. Maybe my setup was somehow wrong from the beginning. I agree with you though, that, in theory I should just be putting the fat end backwards. I'm just gonna put the stockers back on this weekend, measure and make sure the shimmy is gone. Then put the drops back on and get the same angles. I'll post back on Monday. Thanks for straightening me out though.

My problem still is that my pinion still points at a greater angle upward than my DS, so I still have a + pinion when all the reading I've done says it should be 0 or negative. Maybe my setup was somehow wrong from the beginning. I agree with you though, that, in theory I should just be putting the fat end backwards. I'm just gonna put the stockers back on this weekend, measure and make sure the shimmy is gone. Then put the drops back on and get the same angles. I'll post back on Monday. Thanks for straightening me out though.

Last edited by agreif; 09-07-2006 at 12:20 PM.

#13

11 Second Club

iTrader: (1)

Join Date: Feb 2003

Location: Allen,Texas

Posts: 499

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by agreif

measured the pinion angle both on the flatt on that diff housing, and on the actual pinion "yolk" that attached to the driveshaft, both read 5-6. didn't measure the trans though. Looks like that needs to be measured too. Guess I just assumed that was 0.

#14

12 Second Truck Club

iTrader: (3)

Join Date: Feb 2006

Location: Baton Rouge

Posts: 1,457

Likes: 0

Received 0 Likes

on

0 Posts

U-joints cause vibration when the angles front and rear (tranny and pinion) are different because at a given angle the u- joint causes a vibration. The opposing u-joint which is at the opposite end of the shaft and is in phase basically cancels out the vibration with an opposing vibration. If they don't match closely, they will not cancel each other out and you will feel the vibration. That's the way I understand it.

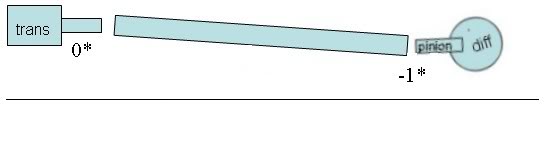

Colby, I do dispute your theory to a point. Not saying it is totally wrong, but your picture does not take the rest of the driveline into account and only focuses on getting the pinion back to the stock angle. Yes the pinion is rotated down, but in most cases, it needs to be. I can promise you that there are trucks that have shackles only installed and still have a high pinion angle, which is opposite of what you depict in your picture. Also, to make your image more accurate, you should have not lowered the front hanger and you should have included the tranny in the pic. If the hanger was stationary, then the rotation of the axle would be more accurate and if the tranny was included in the picture, then the relationship of rear pinion to tranny tailshaft could be compared. But, if not to scale, it's pointless anyway.

IMO there are 2 rules to driveshaft allignment.

(1) If you have a standard 2 u-joint shaft, the tailshaft and pinion angles should be within a degree or two of each other (pinion down for axle wrap)

(2) If running a cv shaft, the pinion should point at the tailshaft (of couse down a degree or two for axle wrap)

Colby, I do dispute your theory to a point. Not saying it is totally wrong, but your picture does not take the rest of the driveline into account and only focuses on getting the pinion back to the stock angle. Yes the pinion is rotated down, but in most cases, it needs to be. I can promise you that there are trucks that have shackles only installed and still have a high pinion angle, which is opposite of what you depict in your picture. Also, to make your image more accurate, you should have not lowered the front hanger and you should have included the tranny in the pic. If the hanger was stationary, then the rotation of the axle would be more accurate and if the tranny was included in the picture, then the relationship of rear pinion to tranny tailshaft could be compared. But, if not to scale, it's pointless anyway.

IMO there are 2 rules to driveshaft allignment.

(1) If you have a standard 2 u-joint shaft, the tailshaft and pinion angles should be within a degree or two of each other (pinion down for axle wrap)

(2) If running a cv shaft, the pinion should point at the tailshaft (of couse down a degree or two for axle wrap)

#16

TECH Junkie

Join Date: Jul 2005

Location: Lake Conroe Texas

Posts: 3,205

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by BigCountryx

Colby, I do dispute your theory to a point. Not saying it is totally wrong, but your picture does not take the rest of the driveline into account and only focuses on getting the pinion back to the stock angle. Yes the pinion is rotated down, but in most cases, it needs to be. I can promise you that there are trucks that have shackles only installed and still have a high pinion angle, which is opposite of what you depict in your picture. Also, to make your image more accurate, you should have not lowered the front hanger and you should have included the tranny in the pic. If the hanger was stationary, then the rotation of the axle would be more accurate and if the tranny was included in the picture, then the relationship of rear pinion to tranny tailshaft could be compared. But, if not to scale, it's pointless anyway.

The point was to show, in theory, what effect the shackles have on the differential - I could give a flying **** less if it's to scale or has accurate real world angles

goodday

#17

12 Second Truck Club

iTrader: (3)

Join Date: Feb 2006

Location: Baton Rouge

Posts: 1,457

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Colby 04

oh I'm sorry it's not to scale and doesn't depict an accurate pinion angle

The point was to show, in theory, what effect the shackles have on the differential - I could give a flying **** less if it's to scale or has accurate real world angles

goodday

The point was to show, in theory, what effect the shackles have on the differential - I could give a flying **** less if it's to scale or has accurate real world angles

goodday

And more than being to scale, both angles need to be taken into account not just the pinion angle. that's my point regardless if you give a flying **** or not.

#19

TECH Junkie

iTrader: (2)

Join Date: Mar 2005

Location: Spring, TX

Posts: 3,197

Likes: 0

Received 0 Likes

on

0 Posts

For example: If you have to use a carrier bearing relocator bracket the trans and carrier bearing will not be lined up anymore. Correct?

Then a tranny shim would be needed.

The final tailshaft of course would be lined up like you guys are stating, the carrier bearing acting as the tranny snout.

I will be definetely doing this the right way, and not half *** like most seem to be doing.

Jim

Then a tranny shim would be needed.

The final tailshaft of course would be lined up like you guys are stating, the carrier bearing acting as the tranny snout.

I will be definetely doing this the right way, and not half *** like most seem to be doing.

Jim

#20

TECH Junkie

Join Date: Jul 2005

Location: Lake Conroe Texas

Posts: 3,205

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by BigCountryx

Get as mad as you want, but you are not 100% correct. Your theory is that the fat end of the shim always goes to the back and you pinion always needs to be angled upward because shackles point you pinion down. You are wrong because depending on the vehicle, you may need to angle your pinion even farther downward, or maybe none at all.

And more than being to scale, both angles need to be taken into account not just the pinion angle. that's my point regardless if you give a flying **** or not.

And more than being to scale, both angles need to be taken into account not just the pinion angle. that's my point regardless if you give a flying **** or not.

you can point out mistakes in that drawing all day long - it was made in about 10 minutes with ms paint - do you really think I was aiming for it to be drawn to scale and replicate accurate angles? NO

BTW, I'm not mad at all, so carry on whicha bad self