alignment bushings ?

#12

Putting these alignment bushings in is a f*****g douche.

I think I'll bring them to someone to press in, this rental tool crap is useless. I built my own jig and that's not working either.

All its doing is bending the outer washer and destroying the outer bushing.

My homemade jog bushed out the oe bushings with ease. I wish I could say the same for installing the new ones. Lube and all, s***s a mess.

That's my alignment bushing rant

Off to a shop haha

I think I'll bring them to someone to press in, this rental tool crap is useless. I built my own jig and that's not working either.

All its doing is bending the outer washer and destroying the outer bushing.

My homemade jog bushed out the oe bushings with ease. I wish I could say the same for installing the new ones. Lube and all, s***s a mess.

That's my alignment bushing rant

Off to a shop haha

#13

It was too late for any shop to press in my bushings, awesome. So, I called a buddy who thankfully has a press. Just got home and the installation of the last two went well and adjusted the first to to the specs from BTs instructions.

This is what gets me. Bell Tech sells these kits but does not state or include in any of the directions about an installation tool, it says "requires specialty tools" and this "The follow steps require special bushing press equipment and should only be performed by a professional with such equipment.".

The BT tool IS needed to install these bushings. OR, you can use a socket that fits the diameter of the inner sleeve to press them in as well.

I'm also not sure if the outer washer is supposed to be removed while pressing in or what. Its not stated in the directions.

Another observation is the bushing itself. It seems rather soft, yes its rubber I know. I'd love to have a better quality bushing in its place. Maybe Poly, if its even available.

Can poly bushings be made for this application?

This is what gets me. Bell Tech sells these kits but does not state or include in any of the directions about an installation tool, it says "requires specialty tools" and this "The follow steps require special bushing press equipment and should only be performed by a professional with such equipment.".

The BT tool IS needed to install these bushings. OR, you can use a socket that fits the diameter of the inner sleeve to press them in as well.

I'm also not sure if the outer washer is supposed to be removed while pressing in or what. Its not stated in the directions.

Another observation is the bushing itself. It seems rather soft, yes its rubber I know. I'd love to have a better quality bushing in its place. Maybe Poly, if its even available.

Can poly bushings be made for this application?

#15

I got the kit with just the bushings, no jig or cam plates. BT kit#4955

Is that jig for installation as well as removal?

Its funny because I brought it to my friends house last night who has that press. It worked great.

I ended up ordering new bushings. I was not happy with the install of the first set.

Both outer washers and bushings were damaged. Fixing the washer was not a problem but the bushing is damaged too much and I cant drive around with it in its state and feel good.

Is that jig for installation as well as removal?

Its funny because I brought it to my friends house last night who has that press. It worked great.

I ended up ordering new bushings. I was not happy with the install of the first set.

Both outer washers and bushings were damaged. Fixing the washer was not a problem but the bushing is damaged too much and I cant drive around with it in its state and feel good.

#18

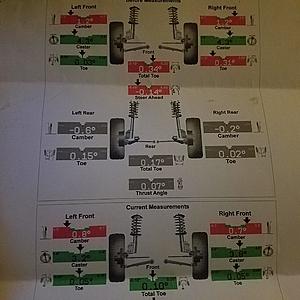

Well, here it is after finally getting everything installed. Looks good, hah.

My question is about my alignment.

After the tech spent some time trying to get it to spec, he couldn't get it any better than 0.8 drivers front and 0.7 passenger front. Both boxes are red, not green. I guess I can only post 1 picture at a time.

He mentioned something about the arms being too long and pushing the tire out.

Can someone confirm the need for alignment bushings for a 4" drop?

I might have to grab another set of MOOG uppers and keep the ones with the alignment bushings for if I want to go lower in the future. Though I'll eventually be converting to coil-overs, not sure if they're necessary.

My question is about my alignment.

After the tech spent some time trying to get it to spec, he couldn't get it any better than 0.8 drivers front and 0.7 passenger front. Both boxes are red, not green. I guess I can only post 1 picture at a time.

He mentioned something about the arms being too long and pushing the tire out.

Can someone confirm the need for alignment bushings for a 4" drop?

I might have to grab another set of MOOG uppers and keep the ones with the alignment bushings for if I want to go lower in the future. Though I'll eventually be converting to coil-overs, not sure if they're necessary.