Guess I'll start one of these, 6.2/ 4l80e NBS

#21

TECH Senior Member

iTrader: (5)

Its too far from the source to pick it up, if you start tapping the block with a hammer on the right side it may see a weak signal but if it were on the right side you would see a strong signal... its a good test but with as sensitive as sensors are its way beyond what spark knock would typically cause(hammer test that is)

#22

Got it on the other side and extended the harness. Ran into one snag, crank pulley must have got hit during shipping I didn't notice it until now. Swapped pulleys from my other motor but couldn't install it with no tool. Got some threaded rod today and some nuts, how is everyone tightening the nut down on the lulled with it sitting so far in? I could just get a piece of steel tubing and usee it as a spacer but last time I made one the tubing bent and messed up the threads. I had a hawk tool do the same thing as well so so I'm not wanting to do that

The following users liked this post:

SCChevy (03-03-2017)

#29

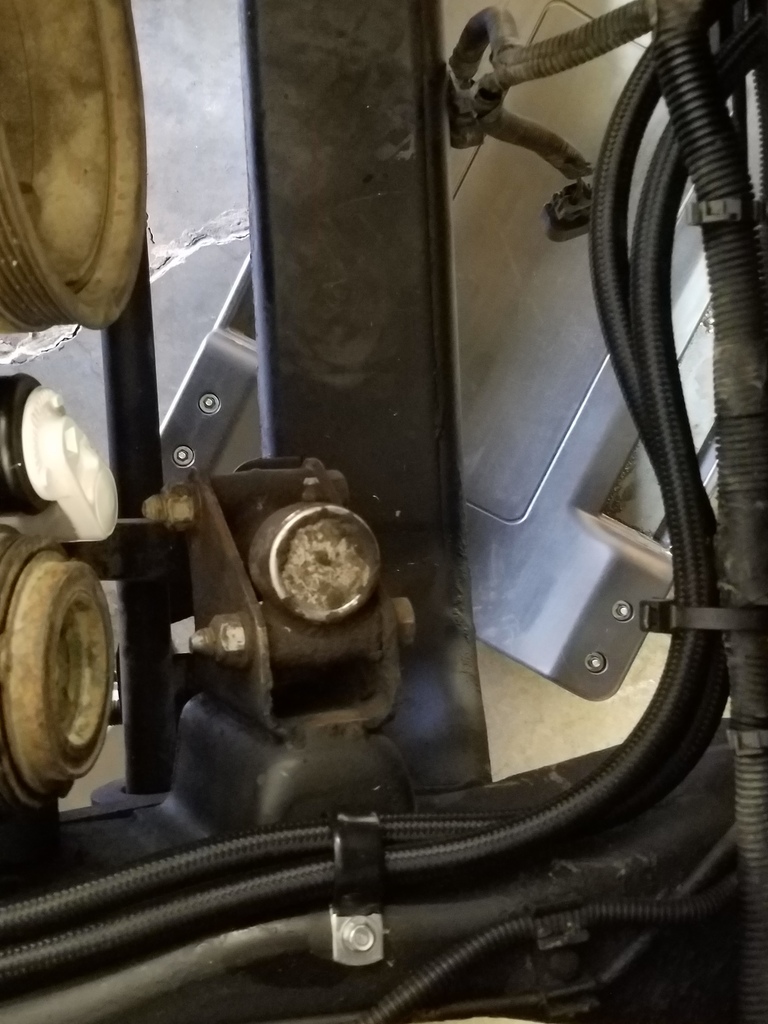

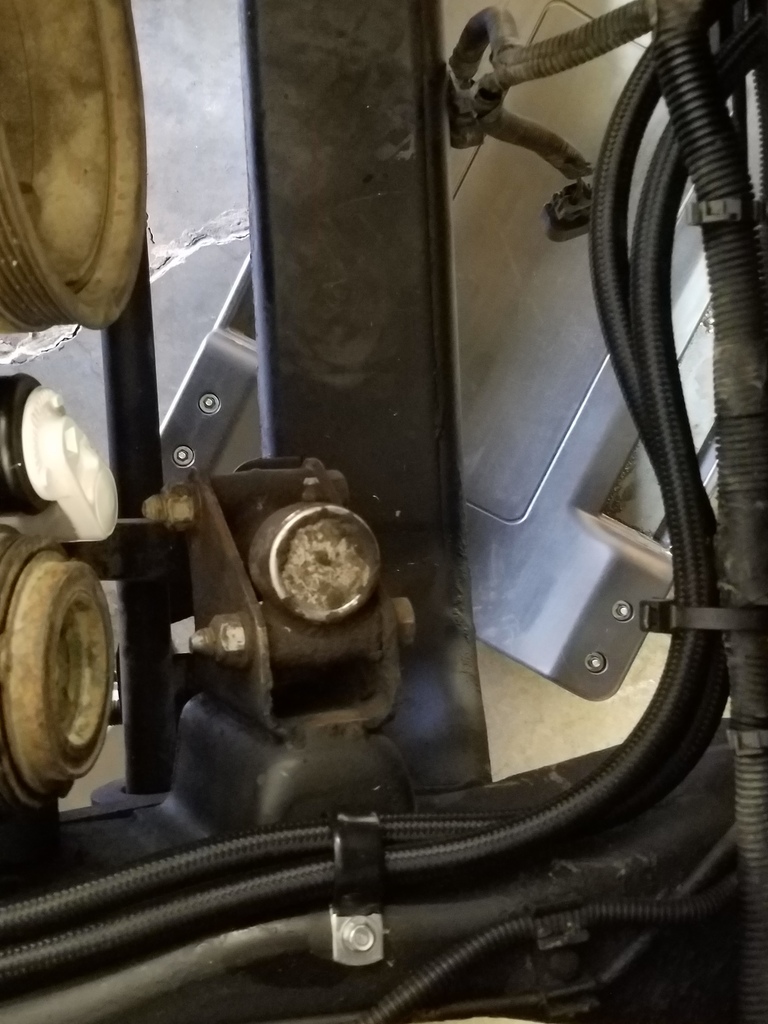

Ran my transmission lines and wrapped my headers. Have one left to do but let me know what you guys think. Only way I could really wrap them since they touch in spots. Used one of the same clamps I used on the frame and mounted it to the starter bolt. Worked well to keep he Iines away from the header.

Last edited by parks450; 10-25-2016 at 04:33 PM.

#30

Anyone who has done a 4l80e swap mind checking this write up to see if it will work? They are similar to way I found here, but a little different. It's the one i used so just want to be sure

4L60E to 4L80E Conversion

4L60E to 4L80E Conversion