Dynojet Wideband Sensor Installation

#1

TECH Enthusiast

Thread Starter

I just finished the installation of a Dynojet Wideband Commander on my truck. Last month I installed a Snow Performance Methanol kit and using the Wideband will make the tuning more precise. The installation is straight forward but does require the welding of a bung on the exhaust pipe.

Here is the project motor.

Everything is included in the kit for the installation.

First step was to install the bung onto the exhaust. I went to the left down pipe before the catalytic converter.

Then I installed the sensor and ran the wiring harness up to the left front fender where the module is mounted. I secured it to the inner fender by the fuse box.

The harness comes with the connector to plug into the sensor. At the other end it has bear wires that need to be put into the module. The cable comes with extra wire, it is cut to fit.

There is another harness to install the requires 2 grounds and 1 switched power.

There is another harness that is ran from the module to the gauge inside. I ran it through the firewall and then into the door. I mounted the gauge just above the door panel with my Aeroforce scan gauge.

I want to thank Dan at Dynojet for his support on this project.

Here is the project motor.

Everything is included in the kit for the installation.

First step was to install the bung onto the exhaust. I went to the left down pipe before the catalytic converter.

Then I installed the sensor and ran the wiring harness up to the left front fender where the module is mounted. I secured it to the inner fender by the fuse box.

The harness comes with the connector to plug into the sensor. At the other end it has bear wires that need to be put into the module. The cable comes with extra wire, it is cut to fit.

There is another harness to install the requires 2 grounds and 1 switched power.

There is another harness that is ran from the module to the gauge inside. I ran it through the firewall and then into the door. I mounted the gauge just above the door panel with my Aeroforce scan gauge.

I want to thank Dan at Dynojet for his support on this project.

#5

Moderately Differentiated

iTrader: (4)

I have the same wideband and have never had any issues with it. I use it to trigger my nitrous since it has relay outputs on it. Use TPS and AFR to turn nitrous on and if it runs too lean opens nitrous circuit.

Actually I did/do have one issue, I for the life of me can't get the RPM to work on it. I have tried all those different techniques too.

#7

11 Second Hall Moniter

iTrader: (22)

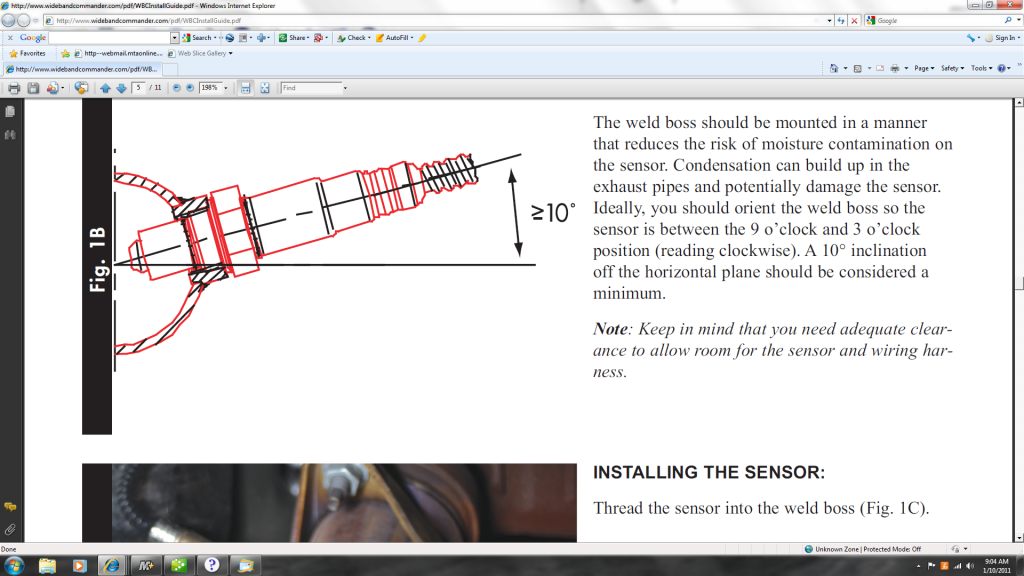

Here's what I was trying to say. As it sits right now, any contaminants or condensation that drips down the inside of the pipe will collect at the sensor. Here's a link to DynoJet's install manual, and a pic. This applies to all oxygen sensors. Just trying to help.

http://www.widebandcommander.com/pdf...stallGuide.pdf

http://www.widebandcommander.com/pdf...stallGuide.pdf

Trending Topics

#8

TECH Fanatic

iTrader: (1)

Join Date: Dec 2003

Location: Halifax, Nova Scotia

Posts: 1,708

Likes: 0

Received 0 Likes

on

0 Posts

[QUOTE=AKlowriderZ71;4614348]Here's what I was trying to say. As it sits right now, any contaminants or condensation that drips down the inside of the pipe will collect at the sensor. Here's a link to DynoJet's install manual, and a pic. This applies to all oxygen sensors. Just trying to help.

I see your point, good point as well.

only real other place to put it would be above o2

I see your point, good point as well.

only real other place to put it would be above o2

Thread

Thread Starter

Forum

Replies

Last Post

zblee

GM Engine & Exhaust Performance

63

06-10-2023 01:25 PM

zblee

GM Engine & Exhaust Performance

15

08-03-2015 03:45 AM