I'm modding a trick cast manifold for 50mm! Pics inside.

#1

Launching!

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: Minnesota

Posts: 299

Likes: 0

Received 0 Likes

on

0 Posts

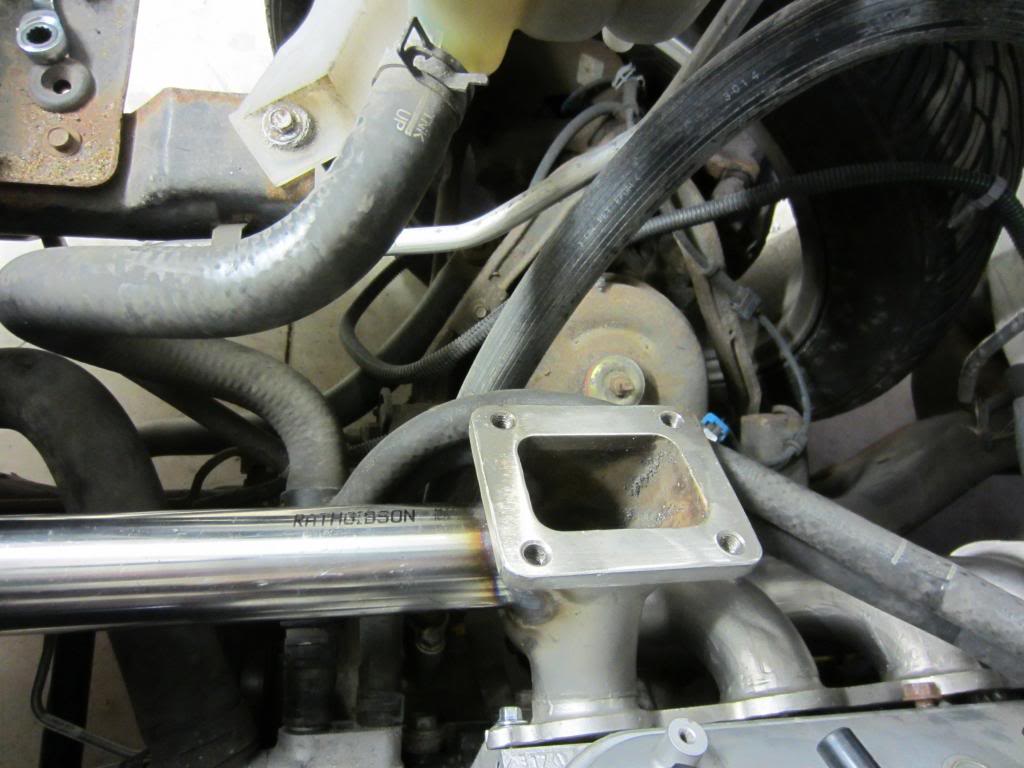

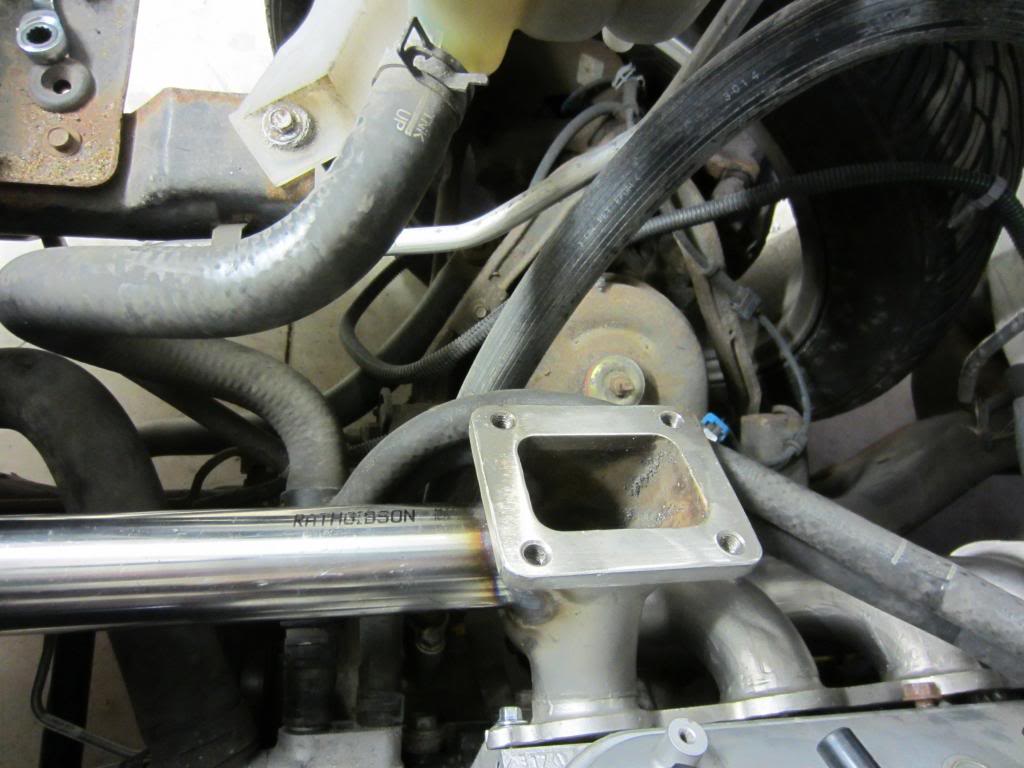

As far as I know, I'm the only person to do this so far. I don't even know of anybody who is using the front wastegate port on theirs so check this out.

I didn't like the idea of running the waste gate on the cross over pipe under the truck, just seems really backwards and not the most efficient for flow. Sure, it works, but I would rather be truly bleeding exhaust from all 8 cylinders.

I started by cutting the built in flange off. This took forever with a sawzall on stainless. I probably have a solid hour of cutting time to get through this.

Finally.

Then opened up the hole from 1.5" to 2" for the 50mm waste gate. The built in flange is for 38mm.

Test fit of new 2" waste gate pipe.

And here is the full length tube tig welded in. This will be cut down once I get the wastegate and down pipe completed.

Not bad for 20 minutes of experience in tig welding!

The waste gate will be V-band mounted straight off the manifold and then exit 90* out to the wheel, wrapping around the A/C line (heat wrapped of course) and then bend into the down pipe. The heater lines will also be rerouted, which is required no matter what. Again, this is not the final length, it will be cut accordingly.

I'll post more progress as I get there.

I didn't like the idea of running the waste gate on the cross over pipe under the truck, just seems really backwards and not the most efficient for flow. Sure, it works, but I would rather be truly bleeding exhaust from all 8 cylinders.

I started by cutting the built in flange off. This took forever with a sawzall on stainless. I probably have a solid hour of cutting time to get through this.

Finally.

Then opened up the hole from 1.5" to 2" for the 50mm waste gate. The built in flange is for 38mm.

Test fit of new 2" waste gate pipe.

And here is the full length tube tig welded in. This will be cut down once I get the wastegate and down pipe completed.

Not bad for 20 minutes of experience in tig welding!

The waste gate will be V-band mounted straight off the manifold and then exit 90* out to the wheel, wrapping around the A/C line (heat wrapped of course) and then bend into the down pipe. The heater lines will also be rerouted, which is required no matter what. Again, this is not the final length, it will be cut accordingly.

I'll post more progress as I get there.

Last edited by cpolaris502; 05-05-2014 at 09:26 PM.

#4

Launching!

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: Minnesota

Posts: 299

Likes: 0

Received 0 Likes

on

0 Posts

I thought about doing that too but you're still forcing all your waste exhaust through that little 38mm hole. The smallest part is still going to be your restriction.

Pretend you drilled a 1/16" hole into a plastic bottle cap and try to blow through it. It doesn't matter what's on the other side of the hole, you can only get so much air through there.

Pretend you drilled a 1/16" hole into a plastic bottle cap and try to blow through it. It doesn't matter what's on the other side of the hole, you can only get so much air through there.

Trending Topics

#8

TECH Resident

iTrader: (4)

im with you i dont really like the idea of the WG in the x-over pipe. Im just doing a quick 90 elbow off my manifold. worse comes to worse and it doesnt work out its not hard to pull the manifold and cut it up like you did. I have a carbite tool that should be able to smooth out and open up that 38mm to slightly larger port