I broke'did my toy... Kenne Bell/370 rebuild

#44

Made a little progress on the engine assembly on Saturday. Bores measured alot better than they did first time around. I measured between .0035 and .0045 on all cylinders with the mains installed but not torqued and no head or torque plate. The block was bored/honed with a torque plate this time so I am trusting once everything is torqued up the cylinders will distort to true out the bores. Wiseco recommends .0040 clearance so I think I am in good shape, much better than the .007 I was getting with the first machinist. Main bearing clearances are all between .002-.003 per plastigauge. I am a little concerned with the crank endplay I measured though. Using a large prybar between the counterweights and #2 main, I got .010-.012 depending on how much forced I used. GM spec is .0015-.0078. From my research I have found testimonial of up to .0250 without adverse affects on auto cars but .030 is about where counterweights will start contacting mains. Some also say too much thrust will cause crank trigger read problems at high rpm. Any of you have and opinion or experience with too much crank endplay?

#47

I have a lot of pics to go thru and upload to share about the build but I did get her running today. Seems to be running great. Tune wasn't too far off, 5-10% lean across the board. I tried to do a little tuning today while seating the rings but it is difficult with tourist traffic this close to the holiday. Tomorrow I may go do a late night tuning session.

KB 371ci - First Startup - YouTube

KB 371ci - First Startup - YouTube

#50

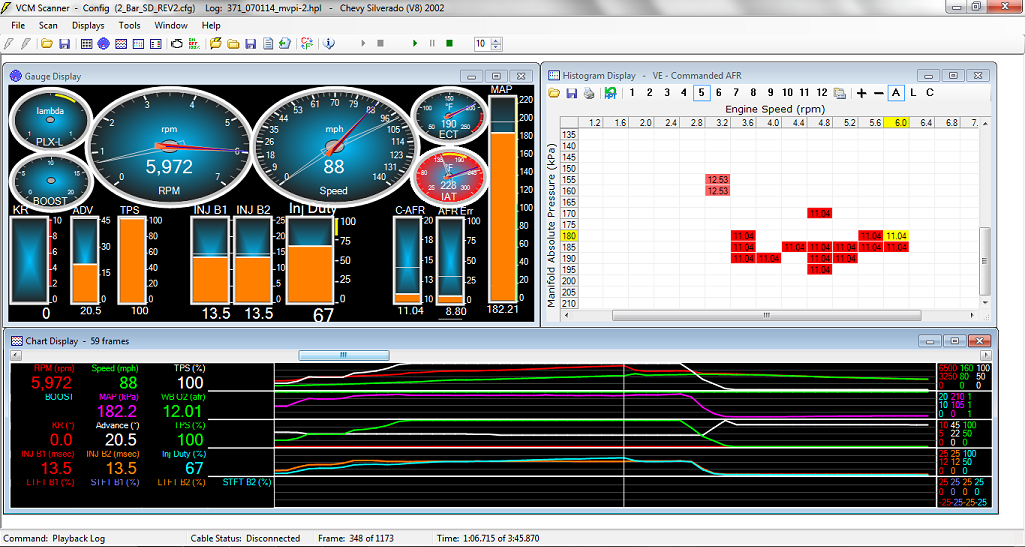

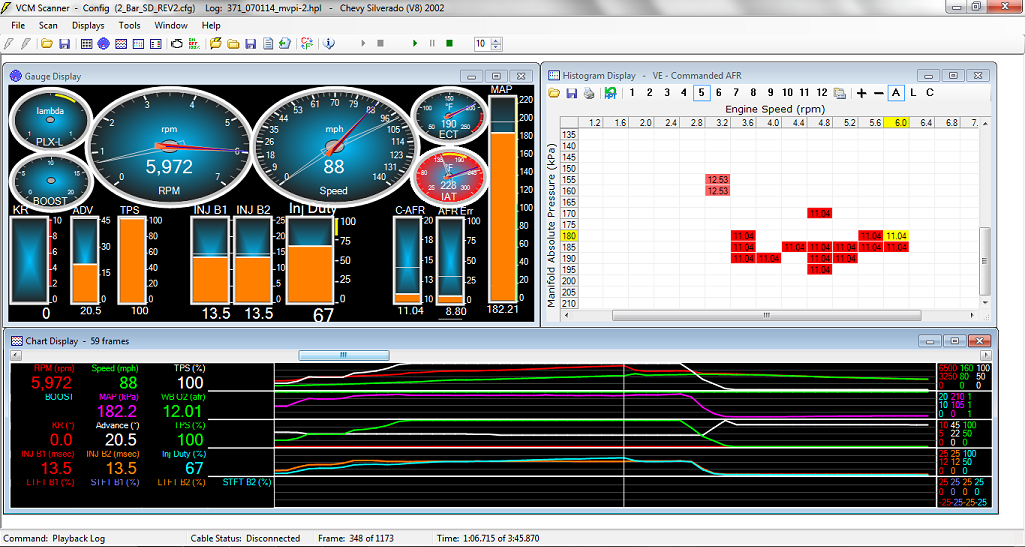

Did my first WOT stint on the new engine today, although a bit unexpectedly. Happened to get beside a new Porsche Caman 4S that was feeling a bit inclined. My laptop was dead but I did have my HPT cable hooked up and logged it using the MVPI. It felt really good and confirmed my boost prediction of around 12psi. Here is a snapshot of the run...

I can't remember what config I put in the MVPI so that is why some of the pids arn't displaying correctly.

Overall I am really happy with the way the new heads and cam are working. I am going to have to address my exhaust though. The 4" Magnaflow has become very raspy in the 2000-2500rpm range under load. That is right where my converter is during moderate acceleration so it is very annoying and embarrassing.

I can't remember what config I put in the MVPI so that is why some of the pids arn't displaying correctly.

Overall I am really happy with the way the new heads and cam are working. I am going to have to address my exhaust though. The 4" Magnaflow has become very raspy in the 2000-2500rpm range under load. That is right where my converter is during moderate acceleration so it is very annoying and embarrassing.

Last edited by BigKID; 07-01-2014 at 06:56 PM.