Gear pattern help from experts

#31

Yeah not sure how you're supposed to have the tires bolted up without axles or a carrier in place

Anyways, got the old seal out very easily with a prybar and didn't damage it. I'm going to keep that in the parts bin and use a brand new one from my Yukon rebuild kit. Hopefully tackle it tonight or this weekend, wish me luck

Anyways, got the old seal out very easily with a prybar and didn't damage it. I'm going to keep that in the parts bin and use a brand new one from my Yukon rebuild kit. Hopefully tackle it tonight or this weekend, wish me luck

#33

TECH Enthusiast

I meant to say when it's under the truck bolted up it's easier to preload when it's stable instead of being on jack stands. Not setting on the tires.... LOL Sorry if I confused everyone.

RT

RT

#35

TECH Senior Member

iTrader: (87)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 19,145

Likes: 0

Received 8 Likes

on

8 Posts

Nah, the pattern should be fine. It generally doesnt shift. It does seem like the backlash tightens by about .001 when swapping from used mock up bearings to brand new ones.

#37

Alright so I did the reassembly. I wanted some input from you guys. I got the pinion bearing pre-load in between 19-20 in-lbs and Yukon calls for 14-19in-lbs. Would you guys run that?

also, it tightened up my backlash with all the final hardware to 6 when it was originally 7, but spec is 6-10 so I'm good there.

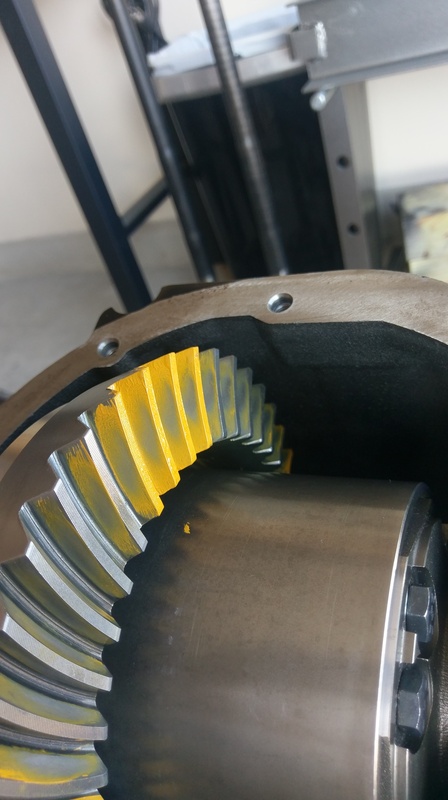

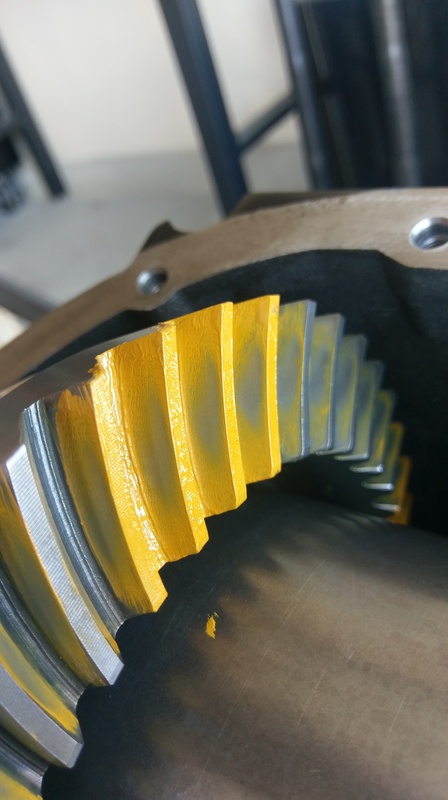

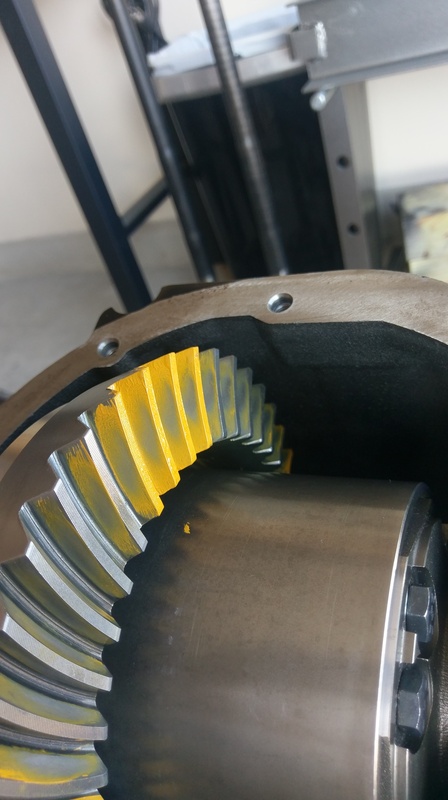

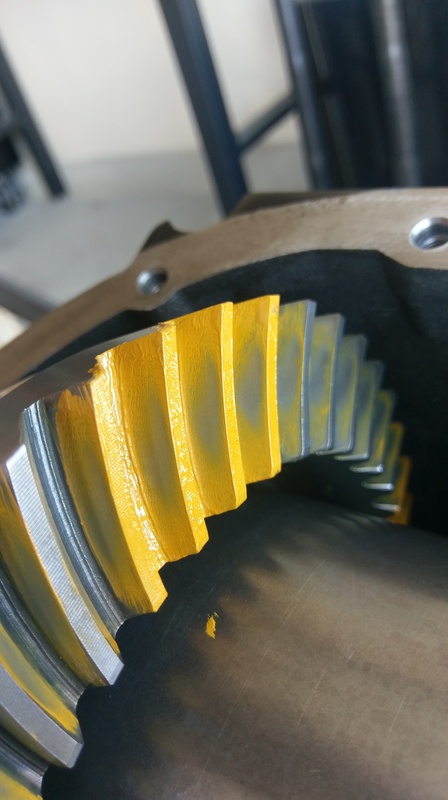

here is the final pattern with everything torqued down, it seemed to change slightly

also, it tightened up my backlash with all the final hardware to 6 when it was originally 7, but spec is 6-10 so I'm good there.

here is the final pattern with everything torqued down, it seemed to change slightly

#38

And is a clunk noise normal when you go from one direction to the other? See the video for example

http://s83.photobucket.com/user/ILuvJDM/media/2006%20Silverado/VIDEO0044_zpsvwvlt7sd.mp4.html

<embed width="600" height="361" type="application/x-shockwave-flash" allowFullscreen="true" allowNetworking="all" wmode="transparent" src="http://static.photobucket.com/player.swf" flashvars="file=http%3A%2F%2Fvid83.photobucket.com %2Falbums%2Fj285%2FILuvJDM%2F2006%2520Silverado%2F VIDEO0044_zpsvwvlt7sd.mp4&title=">

http://s83.photobucket.com/user/ILuvJDM/media/2006%20Silverado/VIDEO0044_zpsvwvlt7sd.mp4.html

<embed width="600" height="361" type="application/x-shockwave-flash" allowFullscreen="true" allowNetworking="all" wmode="transparent" src="http://static.photobucket.com/player.swf" flashvars="file=http%3A%2F%2Fvid83.photobucket.com %2Falbums%2Fj285%2FILuvJDM%2F2006%2520Silverado%2F VIDEO0044_zpsvwvlt7sd.mp4&title=">

#39

TECH Regular

iTrader: (3)

I would not worry about 19-20 in-lb when the spec goes to 19. The seal will add some drag like I mentioned before. Still seems like you don't have enough oil in the gear marking compound. The pattern isn't too clear. Was it a chocolate syrup consistency? Try adding more oil and running it again. It should show up similar to the pictures I posted.

#40

I'll have to redo that tomorrow, I put the cover on and wrapped it up for the night to go out with friends.

Any input on the noise? I know backlash in theory is the amount of movement before contact, so it makes sense that there would be a metal clank sound when the gears hit each other... but I wanted to be sure because I don't recall if that was there during setup or not. There is no fluid in the diff either so it's just clean metal to clean metal

Any input on the noise? I know backlash in theory is the amount of movement before contact, so it makes sense that there would be a metal clank sound when the gears hit each other... but I wanted to be sure because I don't recall if that was there during setup or not. There is no fluid in the diff either so it's just clean metal to clean metal